Micro motion study in industrial engineering pdf

Industrial Engineering can also assist by developing systems for maintaining methods and updating schedules. Motion economy and methods analysis are used by industrial engineering for effective use of capital.The man-made instruments of production – Materials,Machinery, and Facilities- can be analyzed trial engineering.By providing in the management and control of and-evaluated by this …

Micro motion and macro-motion study: Principles of motion economy. Employees provident fund scheme 1952. Work measurement techniques . sources of industrial finance. Payment of bonus act 1965. Factories act 1948. Quality assurance. variable and attributes.time 04 study. pre-determined motion time standards (PMTS) Determination of time standards. Industrial Engineering and …

The app is a complete free handbook of Industrial Engineering which covers important topics, notes, materials, news & blogs on the course. Download the App as a reference material & digital book for Mechanical engineering programs & degree courses.

To become a professionally accredited engineer, you will complete five years of study, starting with an engineering major in a three-year undergraduate degree, followed by a two-year Master of Engineering.

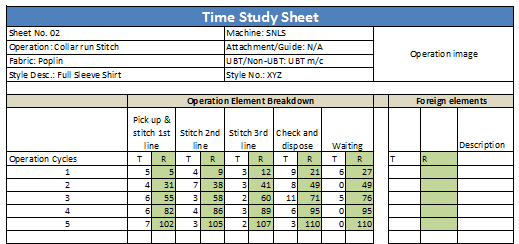

Time and Motion Study Equipment A stop-watch Time study forms A study board Other Equipments: •Audio and Video Tape recorder • Stationary • Equipments related with particular field. Preparing for a Time Study The steps in the process studied must already be standardized; e.g. sequences have been determined. All the information about staff members should be available in library. Operator

Industrial and Manufacturing Systems Engineering Theses and Dissertations . Follow Theses/Dissertations from 2018 PDF. The implication of rapid technologies on the design process, Esra’a Abdel-All. PDF. Adopting and incorporating crowdsourced traffic data in advanced transportation management systems, Mostafa Amin-Naseri. PDF. Solution methods and bounds for two-stage risk …

industrial engineering groups, work simplification and value analysis programs, suggestion systems, quality circles, and other methods of achieving reduced costs of manufacturing their products. One of the consequences of these programs has been increased mechanization, which, in turn, has led to the production of more and more goods per work hour. Among the long-range benefits derived from

WORK Analysis and Design Laboratory Manual Prepared by: Dr. Tamer Mohamed Ahmed Khalaf . 2 Department of Industrial Engineering College of Engineering King Saud University, KSA Preface This manual is intended for undergraduate industrial engineering students as well as for beginners in Work Analysis and Design. It provides the broad knowledge about the areas of methods, measurement, …

Charts Used in Motion Study 5 Types Economics Discussion

https://youtube.com/watch?v=K-t5bTLU6rc

Micromotion study Article about micromotion study by The

actually do and Gilbreths were charged with the task of proving that motion study particularly, and scientific management generally, increased industrial output in ways which improved and did not detract from workers’ mental and physical strength. ISSN: 2319-8753 International Journal of Innovative Research in Science, Engineering and Technology (ISO 3297: 2007 Certified Organization) Vol. 2

thermofluids, manufacturing, materials, solid mechanics, and industrial engineering. The student presents the project plan in writing, The student presents the project plan in writing, and the project is carried out under the guidance of the supervisor.

Industrial Engineering UNIT ±II Method study Prepared By Prof. Shinde Vishal Vasant Assistant Professor Dept. of Mechanical Engg. 1’093¶6 Karmaveer Baburao Thakare

The following points highlight the five main types of charts used in motion study. The types are: 1. Operation Process Chart 2. Flow Diagram 3.

“Thus micro-motion study is the technique of recording and analysing the timing of basic elements of a operation with the objective of achieving the best method of performing the operation.”

TAMIL NADU PUBLIC SERVICE COMMISSION POST OF PRINCIPAL / ASSISTANT DIRECTOR (TRAINING) INCLUDED IN THE TAMIL NADU EMPLOYMENT AND TRAINING SERVICE INDUSTRIAL ENGINEERING (DEGREE STANDARD) UNIT I – Work System Design Total work content and ineffective time – productivity – concepts and measurements, factors affecting productivity, method study – tools and techniques, micro-motion study

MEC441:INDUSTRIAL ENGINEERING L:2 T:0 P:0 Credits:2 Course Objectives: • To impart the knowledge of optimizing the resources of industry by use of various methods of industrial engineering. • Understand and apply the principles of science, technology, engineering, and math involving industry-relevant problems. • Contribute to the proftable growth of industrial economic sectors by using

Syllabus for Production and Industrial Engineering (PI) ENGINEERING MATHEMATICS Linear Algebra: Matrix algebra, Systems of linear equations, Eigen values and eigen vectors.

The Industrial Engineering Terminology Standard defines Time study is a direct and continuous observation of a task, using a time keeping device e.g., decimal minute stopwatch, computer-assisted electronic stopwatch, and videotape camera to record the time taken to accomplish a task. The success of any mass production depends upon the interchangeability to facilitate easy assembly and

12/06/2016 · Principles of Motion Economy As Related to the Design of Tools and Equipment 18. The hands should be relieved of all work that can be done more advantageously by a jig, a fixture, or a foot-operated device.

Products & Services: The Most Complete Portfolio in the Industry Emerson helps manufacturers achieve top quartile business performance through the industry’s broadest portfolio of technologies to measure, control, optimize and power their operations – and the experience and expertise to …

He developed the micro motion study,i.e the subdivision of motion involved in the task.he develops Concept of fatigue in work, and efficency in work-methods 7. 1901 – Henry Gantt- Gantt chart main application solve scheduling problems.

12/06/2016 · Efficiency Improvement Technique of Industrial Engineering Method study is production, service or business process improvement technique _____ Method study is the systematic recording and critical examination of ways of doing things in order to make improvements[1].

Adopt this wiki Edit. This Industrial Engineering Wikia is currently inactive. If you would like to start a new Industrial Engineering wiki here, or revive the old one, please go ahead.

Contents VI 45 3.9 References 47 4 Motion economy 4.1 Principles ofmotioneconomy 47 4.2 Two-handedprocesschart 50 4.3 Micromotion study 4.4 Studyofmethodrecorded

Week 6: String Diagrams, Principles of Motion Economy, Micro-Motion Study, Therbligs, SIMO Charts Week 7: Memo-Motion Study, Cycle graph and Chrono-Cycle Graph, Critical Examination Techniques, Development and Selection of New Method, Installation and Maintenance of Improved Methods.

Work study, therefore, comprises of two areas of study: method study (motion study) and time study (work measurement). Role of Work Study in Improving Productivity In order to understand the role of work study, we need to understand the role of method study and that of time study.

Micro Motion Study Technique: Introduction, Definition, Purpose and Advantages! Introduction: Micro motion study technique is best suited for those operations or activities which are of short duration and which are repeated hundreds of time.

Through various methods of Motion Study (Micro-Motion Study (movie film) and the Chro- nocyclegraph) the Gilbreths were able to examine the smallest of motions. However, to make the

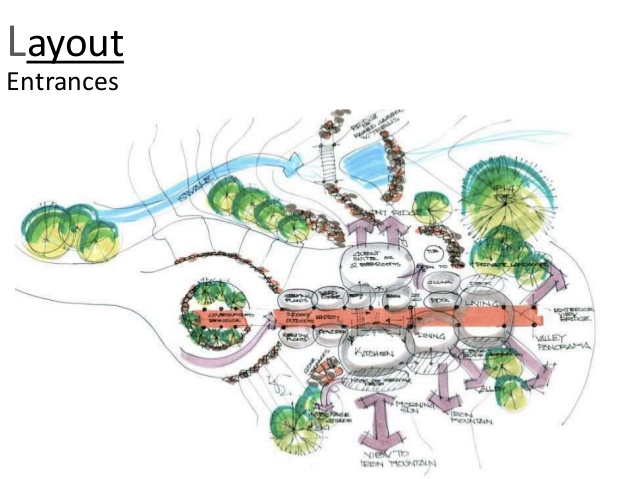

Methods Engineering-Steps – Recording Tools and techniques – Design of work place layout – Motion study – micro motion study – THERBLINGs – cycle graph and chrono cycle graph – SIMO chart – Principles of motion economy.

Mechanical and Industrial Engineering Our professionally based program features advanced study in thermofluids, manufacturing, materials, solid mechanics

https://youtube.com/watch?v=bqBqhSesYtE

JUSTIFICATION AND CRITERIA FOR A PROPOSED WORK STUDY

Safety Engineering (3-0) A study of man-machine environment and the accident cause-effect relationship. Provides an analytic structure through which safety decision-making can be performed in light of changes in the legal, management, and technical aspects of industrial safety.

§Work study improves industrial relations: l Workers feel that the management cares for them. l Workers discover that there are managers who highly understand their job. l Improving the feeling of confidence. l Workers are more able to carry out their jobs. October 03 Lotfi K. Gaafar 10 Work study and the Worker §Why workers resist the work study: l It will change their familiar work methods

The course deals with the subject that industrial engineering has been most identified with: motion and time study, and productivity improvement. Through the course, students get a chance to view

Time and motion study impact the whole production rate of the company. Time and motion study is a method in order to determine the actual time needed to complete task. Problem Statement Time and motion study is the important aspect in business to determine the production rate. Another factor’s that effect the production rate is raw material, operation cost, work force and others. All this

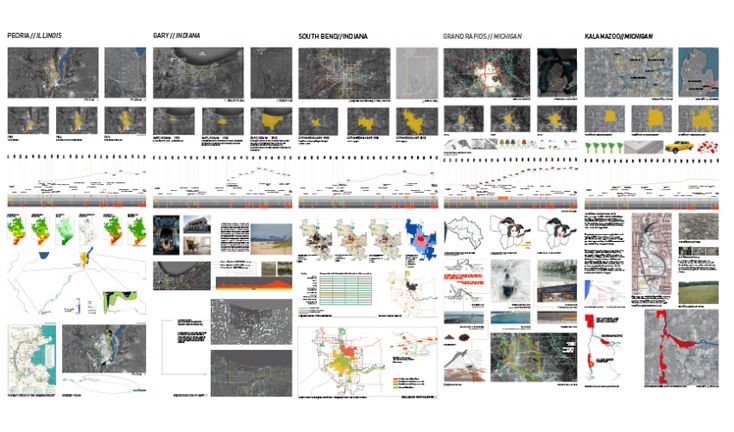

Macromotion study in Industrial Engineering point of view is simply a study that focuses the overall process in the manufacturing company.

Work Measurement consists of various Industrial Engineering techniques including Time Study, Motion Study, Predetermined Motion Time System (PMTS), and MODAPTS. What is Time Study? Time study is a work measurement technique consisting of careful time measurement of the task with a time measuring instrument, adjusted for any observed variance from normal effort or pace and to …

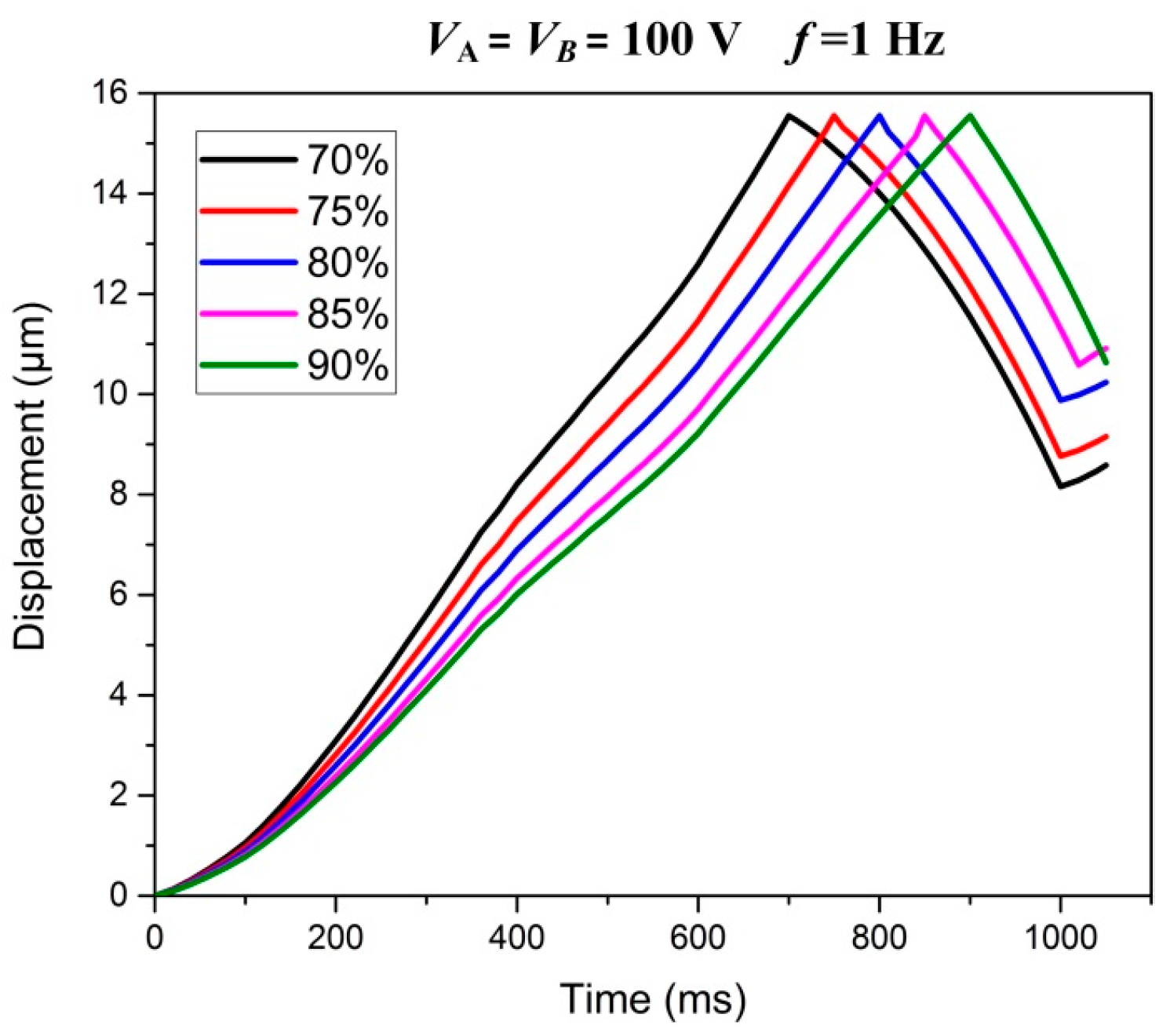

In this paper we review the world-wide study on micro-motion systems both from an academic and an industrial perspective. The objective of the review is to answer the following questions: (1) What are the limitations of technologies to develop a micro-motion device in terms of function, motion range

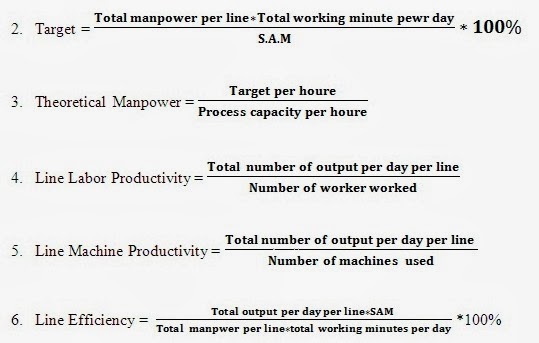

INDUSTRIAL ENGINEERING TIME MOTION STUDY FORMULA PDF READ Industrial Engineering Time Motion Study Formula pdf. Download Industrial Engineering Time Motion Study Formula pdf.

The word therblig was the creation of Frank Bunker Gilbreth and Lillian Moller Gilbreth, American industrial psychologists who invented the field of time and motion study. It is a reversal of the name Gilbreth , with ‘th’ transposed .

JNTUK- B.Tech 3-2 Sem INDUSTRIAL ENGG & MANAGEMENT

3 anna university, chennai affiliated institutions regulations 2017 m.e. industrial engineering choice based credit systems i to iv semesters (full time) curriculum and syllabus

Some Techniques of Industrial Engineering •Measure – Time and Motion Study – Work Sampling • Control – Work Standards (Best Practices) – Accounting – Labor Reporting • Improve – Small group activities. Time Study • Observation –Sotp Wacth – Computer / Interactive • Engineering Labor Standards (Bad Idea) • Job Order / Labor reporting data. History • Frederick

One of the important Industrial Engineering activities is to analyze the Job or Workplace. This is to be used for quality and productivity improvement specially the workers activity, working space, materials, machines, jigs and fixtures, tools and other equipment in the

industrial engineering time motion pdf Industrial engineering is an inter-disciplinary profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integrated systems of

JUSTIFICATION AND CRITERIA FOR A PROPOSED WORK STUDY LICENSE LAW A THESIS Presented to The Faculty of the Division of Graduate Studies and Research

2/08/2016 · Download Motion and Time Study for Lean Manufacturing 3rd Edition Pdf Carrie. Loading… Unsubscribe from Carrie? Cancel Unsubscribe. Working… Subscribe Subscribed Unsubscribe 2. …

Therblig Wikipedia

Syllabus for Production and Industrial Engineering (PI)

https://youtube.com/watch?v=VdNhREmkrmE

(industrial engineering) A time and motion study based on the concept that all work is performed by using a relatively few basic operations in varying combinations and sequence; basic elements (therbligs) include grasp, search, move, reach, and hold.

TIME & MOTION STUDY Issue Time & Motion Study TYPE TAGLINE HERE IN THIS ISSUE What A scientific method for collecting and analyzing work tasks in creating employee productivity standards and identifying all “hands-on time” while the entire work process to include, resources, layout, waiting, travel, walk away time, machine, and automation time are collected and documented. How A work …

Time and Motion study D.S.S.C.P.Subasinghe E/04/288 Department of Mechanical Engineering Faculty of Engineering University of Peradeniya Time and Motion study What is time and motion study? This is a business efficiency technique. y d u t s em i •T Frederick W. Taylor and his followers developed and refined the Time Study. • Motion study Frank B. Gilbreth and his wife Lillian …

10/05/2014 · INTRODUCTION: Definition of industrial engineering (IE), Development, applications, role of an industrial engineer, differences between production, management and industrial engineering, quantitative tools of IE and productivity measurement.

28/10/2017 · Introduction to work and motion study, classification of charts and activity symbols, percentage utilization, micro motion study, standard & normal time …

Micro motion study The main purpose of micro motion study was to calculate the overall human activity and these activities are further divided in to the small movements.

Micro-motion study, presented for the first time at this meeting, is a new and accurate method of recording and transmitting skill. Based upon the principles of motion study and time study , it makes possible simultaneous measurement of both time and path of motions.

The important objectives of the motion study are: 1. To improve the process of doing work . 2. To improve the design of work place layout . 3. To find the best way of doing a job

Micro-Motion Study 9. Memo Motion Study 10. Cycle Graph and Chronocycle Graph 11. Critical Examination 12. Development and Selection of New Method 13. Principles of Motion Economy 14. Installation of the Proposed Method 15. Maintain the Proposed Method V. Work Measurement : 1. Definition 2. Objectives of Work Measurement 3. Techniques of Work Measurement 4. Types of Elements 5. Time Study

MEC441INDUSTRIAL ENGINEERING Abhijeet Kumar

Micro-Motion Study Meaning and Advantages Industry

Study of various Industrial Engineering Functions, Work Study (Motion Study and Time Analysis), Economic considerations, Plant Layout, Safety aspects of working, safety gadgets used on machines and personal safety,

Industrial Engineering Knowledge Center Method Study

Industrial Engineering and Production Management by

Work System Design Course

Industrial Engineering FANDOM powered by Wikia

Frank Bunker Gilbreth Sr. Wikiquote

Gilbreth’s micromotion study Article about Gilbreth’s

Motion Study Meaning Objectives and Procedure

Industrial Engineering FANDOM powered by Wikia

MEC441:INDUSTRIAL ENGINEERING L:2 T:0 P:0 Credits:2 Course Objectives: • To impart the knowledge of optimizing the resources of industry by use of various methods of industrial engineering. • Understand and apply the principles of science, technology, engineering, and math involving industry-relevant problems. • Contribute to the proftable growth of industrial economic sectors by using

Macromotion study in Industrial Engineering point of view is simply a study that focuses the overall process in the manufacturing company.

The important objectives of the motion study are: 1. To improve the process of doing work . 2. To improve the design of work place layout . 3. To find the best way of doing a job

In this paper we review the world-wide study on micro-motion systems both from an academic and an industrial perspective. The objective of the review is to answer the following questions: (1) What are the limitations of technologies to develop a micro-motion device in terms of function, motion range

Some Techniques of Industrial Engineering •Measure – Time and Motion Study – Work Sampling • Control – Work Standards (Best Practices) – Accounting – Labor Reporting • Improve – Small group activities. Time Study • Observation –Sotp Wacth – Computer / Interactive • Engineering Labor Standards (Bad Idea) • Job Order / Labor reporting data. History • Frederick

One of the important Industrial Engineering activities is to analyze the Job or Workplace. This is to be used for quality and productivity improvement specially the workers activity, working space, materials, machines, jigs and fixtures, tools and other equipment in the

Work study, therefore, comprises of two areas of study: method study (motion study) and time study (work measurement). Role of Work Study in Improving Productivity In order to understand the role of work study, we need to understand the role of method study and that of time study.

Methods Engineering-Steps – Recording Tools and techniques – Design of work place layout – Motion study – micro motion study – THERBLINGs – cycle graph and chrono cycle graph – SIMO chart – Principles of motion economy.

actually do and Gilbreths were charged with the task of proving that motion study particularly, and scientific management generally, increased industrial output in ways which improved and did not detract from workers’ mental and physical strength. ISSN: 2319-8753 International Journal of Innovative Research in Science, Engineering and Technology (ISO 3297: 2007 Certified Organization) Vol. 2

industrial engineering time motion pdf Industrial engineering is an inter-disciplinary profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integrated systems of

Micromotion study Article about micromotion study by The

Micro-motion devices technology The state of arts review

Micro Motion Study Technique: Introduction, Definition, Purpose and Advantages! Introduction: Micro motion study technique is best suited for those operations or activities which are of short duration and which are repeated hundreds of time.

The following points highlight the five main types of charts used in motion study. The types are: 1. Operation Process Chart 2. Flow Diagram 3.

Industrial Engineering UNIT ±II Method study Prepared By Prof. Shinde Vishal Vasant Assistant Professor Dept. of Mechanical Engg. 1’093¶6 Karmaveer Baburao Thakare

Work study, therefore, comprises of two areas of study: method study (motion study) and time study (work measurement). Role of Work Study in Improving Productivity In order to understand the role of work study, we need to understand the role of method study and that of time study.

Study of various Industrial Engineering Functions, Work Study (Motion Study and Time Analysis), Economic considerations, Plant Layout, Safety aspects of working, safety gadgets used on machines and personal safety,

Through various methods of Motion Study (Micro-Motion Study (movie film) and the Chro- nocyclegraph) the Gilbreths were able to examine the smallest of motions. However, to make the

12/06/2016 · Efficiency Improvement Technique of Industrial Engineering Method study is production, service or business process improvement technique _____ Method study is the systematic recording and critical examination of ways of doing things in order to make improvements[1].

INDUSTRIAL ENGINEERING TIME MOTION STUDY FORMULA PDF READ Industrial Engineering Time Motion Study Formula pdf. Download Industrial Engineering Time Motion Study Formula pdf.

In this paper we review the world-wide study on micro-motion systems both from an academic and an industrial perspective. The objective of the review is to answer the following questions: (1) What are the limitations of technologies to develop a micro-motion device in terms of function, motion range

The important objectives of the motion study are: 1. To improve the process of doing work . 2. To improve the design of work place layout . 3. To find the best way of doing a job

Safety Engineering (3-0) A study of man-machine environment and the accident cause-effect relationship. Provides an analytic structure through which safety decision-making can be performed in light of changes in the legal, management, and technical aspects of industrial safety.

2/08/2016 · Download Motion and Time Study for Lean Manufacturing 3rd Edition Pdf Carrie. Loading… Unsubscribe from Carrie? Cancel Unsubscribe. Working… Subscribe Subscribed Unsubscribe 2. …

Time and Motion study D.S.S.C.P.Subasinghe E/04/288 Department of Mechanical Engineering Faculty of Engineering University of Peradeniya Time and Motion study What is time and motion study? This is a business efficiency technique. y d u t s em i •T Frederick W. Taylor and his followers developed and refined the Time Study. • Motion study Frank B. Gilbreth and his wife Lillian …

Free Industrial Engineering Time Motion Study Formula PDF

Work System Design Course

The course deals with the subject that industrial engineering has been most identified with: motion and time study, and productivity improvement. Through the course, students get a chance to view

Adopt this wiki Edit. This Industrial Engineering Wikia is currently inactive. If you would like to start a new Industrial Engineering wiki here, or revive the old one, please go ahead.

Contents VI 45 3.9 References 47 4 Motion economy 4.1 Principles ofmotioneconomy 47 4.2 Two-handedprocesschart 50 4.3 Micromotion study 4.4 Studyofmethodrecorded

Some Techniques of Industrial Engineering •Measure – Time and Motion Study – Work Sampling • Control – Work Standards (Best Practices) – Accounting – Labor Reporting • Improve – Small group activities. Time Study • Observation –Sotp Wacth – Computer / Interactive • Engineering Labor Standards (Bad Idea) • Job Order / Labor reporting data. History • Frederick

Safety Engineering (3-0) A study of man-machine environment and the accident cause-effect relationship. Provides an analytic structure through which safety decision-making can be performed in light of changes in the legal, management, and technical aspects of industrial safety.

§Work study improves industrial relations: l Workers feel that the management cares for them. l Workers discover that there are managers who highly understand their job. l Improving the feeling of confidence. l Workers are more able to carry out their jobs. October 03 Lotfi K. Gaafar 10 Work study and the Worker §Why workers resist the work study: l It will change their familiar work methods

(industrial engineering) A time and motion study based on the concept that all work is performed by using a relatively few basic operations in varying combinations and sequence; basic elements (therbligs) include grasp, search, move, reach, and hold.

The following points highlight the five main types of charts used in motion study. The types are: 1. Operation Process Chart 2. Flow Diagram 3.

3 anna university, chennai affiliated institutions regulations 2017 m.e. industrial engineering choice based credit systems i to iv semesters (full time) curriculum and syllabus

One of the important Industrial Engineering activities is to analyze the Job or Workplace. This is to be used for quality and productivity improvement specially the workers activity, working space, materials, machines, jigs and fixtures, tools and other equipment in the

The app is a complete free handbook of Industrial Engineering which covers important topics, notes, materials, news & blogs on the course. Download the App as a reference material & digital book for Mechanical engineering programs & degree courses.

12/06/2016 · Principles of Motion Economy As Related to the Design of Tools and Equipment 18. The hands should be relieved of all work that can be done more advantageously by a jig, a fixture, or a foot-operated device.

Micro-Motion Study 9. Memo Motion Study 10. Cycle Graph and Chronocycle Graph 11. Critical Examination 12. Development and Selection of New Method 13. Principles of Motion Economy 14. Installation of the Proposed Method 15. Maintain the Proposed Method V. Work Measurement : 1. Definition 2. Objectives of Work Measurement 3. Techniques of Work Measurement 4. Types of Elements 5. Time Study

Micro-motion study, presented for the first time at this meeting, is a new and accurate method of recording and transmitting skill. Based upon the principles of motion study and time study , it makes possible simultaneous measurement of both time and path of motions.

Industrial Engineering and Production Management by

Industrial Engineering WordPress.com

The app is a complete free handbook of Industrial Engineering which covers important topics, notes, materials, news & blogs on the course. Download the App as a reference material & digital book for Mechanical engineering programs & degree courses.

Products & Services: The Most Complete Portfolio in the Industry Emerson helps manufacturers achieve top quartile business performance through the industry’s broadest portfolio of technologies to measure, control, optimize and power their operations – and the experience and expertise to …

Study of various Industrial Engineering Functions, Work Study (Motion Study and Time Analysis), Economic considerations, Plant Layout, Safety aspects of working, safety gadgets used on machines and personal safety,

The important objectives of the motion study are: 1. To improve the process of doing work . 2. To improve the design of work place layout . 3. To find the best way of doing a job

The Industrial Engineering Terminology Standard defines Time study is a direct and continuous observation of a task, using a time keeping device e.g., decimal minute stopwatch, computer-assisted electronic stopwatch, and videotape camera to record the time taken to accomplish a task. The success of any mass production depends upon the interchangeability to facilitate easy assembly and

10/05/2014 · INTRODUCTION: Definition of industrial engineering (IE), Development, applications, role of an industrial engineer, differences between production, management and industrial engineering, quantitative tools of IE and productivity measurement.

Industrial Engineering can also assist by developing systems for maintaining methods and updating schedules. Motion economy and methods analysis are used by industrial engineering for effective use of capital.The man-made instruments of production – Materials,Machinery, and Facilities- can be analyzed trial engineering.By providing in the management and control of and-evaluated by this …

28/10/2017 · Introduction to work and motion study, classification of charts and activity symbols, percentage utilization, micro motion study, standard & normal time …

(industrial engineering) A time and motion study based on the concept that all work is performed by using a relatively few basic operations in varying combinations and sequence; basic elements (therbligs) include grasp, search, move, reach, and hold.

12/06/2016 · Principles of Motion Economy As Related to the Design of Tools and Equipment 18. The hands should be relieved of all work that can be done more advantageously by a jig, a fixture, or a foot-operated device.

Micro-Motion Study 9. Memo Motion Study 10. Cycle Graph and Chronocycle Graph 11. Critical Examination 12. Development and Selection of New Method 13. Principles of Motion Economy 14. Installation of the Proposed Method 15. Maintain the Proposed Method V. Work Measurement : 1. Definition 2. Objectives of Work Measurement 3. Techniques of Work Measurement 4. Types of Elements 5. Time Study

12/06/2016 · Efficiency Improvement Technique of Industrial Engineering Method study is production, service or business process improvement technique _____ Method study is the systematic recording and critical examination of ways of doing things in order to make improvements[1].

3 anna university, chennai affiliated institutions regulations 2017 m.e. industrial engineering choice based credit systems i to iv semesters (full time) curriculum and syllabus

actually do and Gilbreths were charged with the task of proving that motion study particularly, and scientific management generally, increased industrial output in ways which improved and did not detract from workers’ mental and physical strength. ISSN: 2319-8753 International Journal of Innovative Research in Science, Engineering and Technology (ISO 3297: 2007 Certified Organization) Vol. 2

Industrial Engineering and Production Management by

Industrial Engineering Knowledge Center Method Study

Syllabus for Production and Industrial Engineering (PI) ENGINEERING MATHEMATICS Linear Algebra: Matrix algebra, Systems of linear equations, Eigen values and eigen vectors.

The following points highlight the five main types of charts used in motion study. The types are: 1. Operation Process Chart 2. Flow Diagram 3.

28/10/2017 · Introduction to work and motion study, classification of charts and activity symbols, percentage utilization, micro motion study, standard & normal time …

One of the important Industrial Engineering activities is to analyze the Job or Workplace. This is to be used for quality and productivity improvement specially the workers activity, working space, materials, machines, jigs and fixtures, tools and other equipment in the

Some Techniques of Industrial Engineering •Measure – Time and Motion Study – Work Sampling • Control – Work Standards (Best Practices) – Accounting – Labor Reporting • Improve – Small group activities. Time Study • Observation –Sotp Wacth – Computer / Interactive • Engineering Labor Standards (Bad Idea) • Job Order / Labor reporting data. History • Frederick

Micro-motion study, presented for the first time at this meeting, is a new and accurate method of recording and transmitting skill. Based upon the principles of motion study and time study , it makes possible simultaneous measurement of both time and path of motions.

Micro Motion Study Technique: Introduction, Definition, Purpose and Advantages! Introduction: Micro motion study technique is best suited for those operations or activities which are of short duration and which are repeated hundreds of time.

Industrial and Manufacturing Systems Engineering Theses and Dissertations . Follow Theses/Dissertations from 2018 PDF. The implication of rapid technologies on the design process, Esra’a Abdel-All. PDF. Adopting and incorporating crowdsourced traffic data in advanced transportation management systems, Mostafa Amin-Naseri. PDF. Solution methods and bounds for two-stage risk …

3 anna university, chennai affiliated institutions regulations 2017 m.e. industrial engineering choice based credit systems i to iv semesters (full time) curriculum and syllabus

Industrial Engineering UNIT ±II Method study Prepared By Prof. Shinde Vishal Vasant Assistant Professor Dept. of Mechanical Engg. 1’093¶6 Karmaveer Baburao Thakare

Download Motion and Time Study for Lean YouTube

JNTUK- B.Tech 3-2 Sem INDUSTRIAL ENGG & MANAGEMENT

thermofluids, manufacturing, materials, solid mechanics, and industrial engineering. The student presents the project plan in writing, The student presents the project plan in writing, and the project is carried out under the guidance of the supervisor.

Micro-motion study, presented for the first time at this meeting, is a new and accurate method of recording and transmitting skill. Based upon the principles of motion study and time study , it makes possible simultaneous measurement of both time and path of motions.

Industrial Engineering can also assist by developing systems for maintaining methods and updating schedules. Motion economy and methods analysis are used by industrial engineering for effective use of capital.The man-made instruments of production – Materials,Machinery, and Facilities- can be analyzed trial engineering.By providing in the management and control of and-evaluated by this …

The following points highlight the five main types of charts used in motion study. The types are: 1. Operation Process Chart 2. Flow Diagram 3.

Micro motion and macro-motion study: Principles of motion economy. Employees provident fund scheme 1952. Work measurement techniques . sources of industrial finance. Payment of bonus act 1965. Factories act 1948. Quality assurance. variable and attributes.time 04 study. pre-determined motion time standards (PMTS) Determination of time standards. Industrial Engineering and …

Time and motion study impact the whole production rate of the company. Time and motion study is a method in order to determine the actual time needed to complete task. Problem Statement Time and motion study is the important aspect in business to determine the production rate. Another factor’s that effect the production rate is raw material, operation cost, work force and others. All this

WORK Analysis and Design Laboratory Manual Prepared by: Dr. Tamer Mohamed Ahmed Khalaf . 2 Department of Industrial Engineering College of Engineering King Saud University, KSA Preface This manual is intended for undergraduate industrial engineering students as well as for beginners in Work Analysis and Design. It provides the broad knowledge about the areas of methods, measurement, …

Work Measurement consists of various Industrial Engineering techniques including Time Study, Motion Study, Predetermined Motion Time System (PMTS), and MODAPTS. What is Time Study? Time study is a work measurement technique consisting of careful time measurement of the task with a time measuring instrument, adjusted for any observed variance from normal effort or pace and to …

Download Motion and Time Study for Lean YouTube

IE365 – WORK PRODUCTIVITY ANALYSIS cs.uic.edu

actually do and Gilbreths were charged with the task of proving that motion study particularly, and scientific management generally, increased industrial output in ways which improved and did not detract from workers’ mental and physical strength. ISSN: 2319-8753 International Journal of Innovative Research in Science, Engineering and Technology (ISO 3297: 2007 Certified Organization) Vol. 2

Adopt this wiki Edit. This Industrial Engineering Wikia is currently inactive. If you would like to start a new Industrial Engineering wiki here, or revive the old one, please go ahead.

In this paper we review the world-wide study on micro-motion systems both from an academic and an industrial perspective. The objective of the review is to answer the following questions: (1) What are the limitations of technologies to develop a micro-motion device in terms of function, motion range

2/08/2016 · Download Motion and Time Study for Lean Manufacturing 3rd Edition Pdf Carrie. Loading… Unsubscribe from Carrie? Cancel Unsubscribe. Working… Subscribe Subscribed Unsubscribe 2. …

Time and Motion Study Equipment A stop-watch Time study forms A study board Other Equipments: •Audio and Video Tape recorder • Stationary • Equipments related with particular field. Preparing for a Time Study The steps in the process studied must already be standardized; e.g. sequences have been determined. All the information about staff members should be available in library. Operator

Methods Engineering-Steps – Recording Tools and techniques – Design of work place layout – Motion study – micro motion study – THERBLINGs – cycle graph and chrono cycle graph – SIMO chart – Principles of motion economy.

Through various methods of Motion Study (Micro-Motion Study (movie film) and the Chro- nocyclegraph) the Gilbreths were able to examine the smallest of motions. However, to make the

12/06/2016 · Efficiency Improvement Technique of Industrial Engineering Method study is production, service or business process improvement technique _____ Method study is the systematic recording and critical examination of ways of doing things in order to make improvements[1].

Micro motion study The main purpose of micro motion study was to calculate the overall human activity and these activities are further divided in to the small movements.

Syllabus for Production and Industrial Engineering (PI) ENGINEERING MATHEMATICS Linear Algebra: Matrix algebra, Systems of linear equations, Eigen values and eigen vectors.

TIME & MOTION STUDY Issue Time & Motion Study TYPE TAGLINE HERE IN THIS ISSUE What A scientific method for collecting and analyzing work tasks in creating employee productivity standards and identifying all “hands-on time” while the entire work process to include, resources, layout, waiting, travel, walk away time, machine, and automation time are collected and documented. How A work …

Contents VI 45 3.9 References 47 4 Motion economy 4.1 Principles ofmotioneconomy 47 4.2 Two-handedprocesschart 50 4.3 Micromotion study 4.4 Studyofmethodrecorded

JUSTIFICATION AND CRITERIA FOR A PROPOSED WORK STUDY LICENSE LAW A THESIS Presented to The Faculty of the Division of Graduate Studies and Research

Industrial Engineering Lecture 16 work & motion study

Work System Design Course

§Work study improves industrial relations: l Workers feel that the management cares for them. l Workers discover that there are managers who highly understand their job. l Improving the feeling of confidence. l Workers are more able to carry out their jobs. October 03 Lotfi K. Gaafar 10 Work study and the Worker §Why workers resist the work study: l It will change their familiar work methods

Work Measurement consists of various Industrial Engineering techniques including Time Study, Motion Study, Predetermined Motion Time System (PMTS), and MODAPTS. What is Time Study? Time study is a work measurement technique consisting of careful time measurement of the task with a time measuring instrument, adjusted for any observed variance from normal effort or pace and to …

Mechanical and Industrial Engineering Our professionally based program features advanced study in thermofluids, manufacturing, materials, solid mechanics

Methods Engineering-Steps – Recording Tools and techniques – Design of work place layout – Motion study – micro motion study – THERBLINGs – cycle graph and chrono cycle graph – SIMO chart – Principles of motion economy.

WORK Analysis and Design Laboratory Manual Prepared by: Dr. Tamer Mohamed Ahmed Khalaf . 2 Department of Industrial Engineering College of Engineering King Saud University, KSA Preface This manual is intended for undergraduate industrial engineering students as well as for beginners in Work Analysis and Design. It provides the broad knowledge about the areas of methods, measurement, …

The course deals with the subject that industrial engineering has been most identified with: motion and time study, and productivity improvement. Through the course, students get a chance to view

JUSTIFICATION AND CRITERIA FOR A PROPOSED WORK STUDY LICENSE LAW A THESIS Presented to The Faculty of the Division of Graduate Studies and Research

Macromotion study in Industrial Engineering point of view is simply a study that focuses the overall process in the manufacturing company.

Micro-motion study, presented for the first time at this meeting, is a new and accurate method of recording and transmitting skill. Based upon the principles of motion study and time study , it makes possible simultaneous measurement of both time and path of motions.

In this paper we review the world-wide study on micro-motion systems both from an academic and an industrial perspective. The objective of the review is to answer the following questions: (1) What are the limitations of technologies to develop a micro-motion device in terms of function, motion range

Syllabus for Production and Industrial Engineering (PI)

Charts Used in Motion Study 5 Types Economics Discussion

Some Techniques of Industrial Engineering •Measure – Time and Motion Study – Work Sampling • Control – Work Standards (Best Practices) – Accounting – Labor Reporting • Improve – Small group activities. Time Study • Observation –Sotp Wacth – Computer / Interactive • Engineering Labor Standards (Bad Idea) • Job Order / Labor reporting data. History • Frederick

actually do and Gilbreths were charged with the task of proving that motion study particularly, and scientific management generally, increased industrial output in ways which improved and did not detract from workers’ mental and physical strength. ISSN: 2319-8753 International Journal of Innovative Research in Science, Engineering and Technology (ISO 3297: 2007 Certified Organization) Vol. 2

Mechanical and Industrial Engineering Our professionally based program features advanced study in thermofluids, manufacturing, materials, solid mechanics

industrial engineering time motion pdf Industrial engineering is an inter-disciplinary profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integrated systems of

3 anna university, chennai affiliated institutions regulations 2017 m.e. industrial engineering choice based credit systems i to iv semesters (full time) curriculum and syllabus

Time and Motion study D.S.S.C.P.Subasinghe E/04/288 Department of Mechanical Engineering Faculty of Engineering University of Peradeniya Time and Motion study What is time and motion study? This is a business efficiency technique. y d u t s em i •T Frederick W. Taylor and his followers developed and refined the Time Study. • Motion study Frank B. Gilbreth and his wife Lillian …

He developed the micro motion study,i.e the subdivision of motion involved in the task.he develops Concept of fatigue in work, and efficency in work-methods 7. 1901 – Henry Gantt- Gantt chart main application solve scheduling problems.

12/06/2016 · Efficiency Improvement Technique of Industrial Engineering Method study is production, service or business process improvement technique _____ Method study is the systematic recording and critical examination of ways of doing things in order to make improvements[1].

The course deals with the subject that industrial engineering has been most identified with: motion and time study, and productivity improvement. Through the course, students get a chance to view

Micro-Motion Study 9. Memo Motion Study 10. Cycle Graph and Chronocycle Graph 11. Critical Examination 12. Development and Selection of New Method 13. Principles of Motion Economy 14. Installation of the Proposed Method 15. Maintain the Proposed Method V. Work Measurement : 1. Definition 2. Objectives of Work Measurement 3. Techniques of Work Measurement 4. Types of Elements 5. Time Study

Syllabus for Production and Industrial Engineering (PI) ENGINEERING MATHEMATICS Linear Algebra: Matrix algebra, Systems of linear equations, Eigen values and eigen vectors.

10/05/2014 · INTRODUCTION: Definition of industrial engineering (IE), Development, applications, role of an industrial engineer, differences between production, management and industrial engineering, quantitative tools of IE and productivity measurement.

Safety Engineering (3-0) A study of man-machine environment and the accident cause-effect relationship. Provides an analytic structure through which safety decision-making can be performed in light of changes in the legal, management, and technical aspects of industrial safety.

INDUSTRIAL ENGINEERING TIME MOTION STUDY FORMULA PDF READ Industrial Engineering Time Motion Study Formula pdf. Download Industrial Engineering Time Motion Study Formula pdf.

Syllabus for Production and Industrial Engineering (PI)

JNTUK- B.Tech 3-2 Sem INDUSTRIAL ENGG & MANAGEMENT

Industrial Engineering can also assist by developing systems for maintaining methods and updating schedules. Motion economy and methods analysis are used by industrial engineering for effective use of capital.The man-made instruments of production – Materials,Machinery, and Facilities- can be analyzed trial engineering.By providing in the management and control of and-evaluated by this …

The Industrial Engineering Terminology Standard defines Time study is a direct and continuous observation of a task, using a time keeping device e.g., decimal minute stopwatch, computer-assisted electronic stopwatch, and videotape camera to record the time taken to accomplish a task. The success of any mass production depends upon the interchangeability to facilitate easy assembly and

Time and motion study impact the whole production rate of the company. Time and motion study is a method in order to determine the actual time needed to complete task. Problem Statement Time and motion study is the important aspect in business to determine the production rate. Another factor’s that effect the production rate is raw material, operation cost, work force and others. All this

Safety Engineering (3-0) A study of man-machine environment and the accident cause-effect relationship. Provides an analytic structure through which safety decision-making can be performed in light of changes in the legal, management, and technical aspects of industrial safety.

Time & Motion Study caprockglobal.com

Industrial Engineering Apps on Google Play

§Work study improves industrial relations: l Workers feel that the management cares for them. l Workers discover that there are managers who highly understand their job. l Improving the feeling of confidence. l Workers are more able to carry out their jobs. October 03 Lotfi K. Gaafar 10 Work study and the Worker §Why workers resist the work study: l It will change their familiar work methods

Industrial and Manufacturing Systems Engineering Theses and Dissertations . Follow Theses/Dissertations from 2018 PDF. The implication of rapid technologies on the design process, Esra’a Abdel-All. PDF. Adopting and incorporating crowdsourced traffic data in advanced transportation management systems, Mostafa Amin-Naseri. PDF. Solution methods and bounds for two-stage risk …

The following points highlight the five main types of charts used in motion study. The types are: 1. Operation Process Chart 2. Flow Diagram 3.

3 anna university, chennai affiliated institutions regulations 2017 m.e. industrial engineering choice based credit systems i to iv semesters (full time) curriculum and syllabus

One of the important Industrial Engineering activities is to analyze the Job or Workplace. This is to be used for quality and productivity improvement specially the workers activity, working space, materials, machines, jigs and fixtures, tools and other equipment in the

Industrial Manufacturing and Systems Engineering Courses

JNTUK- B.Tech 3-2 Sem INDUSTRIAL ENGG & MANAGEMENT

Through various methods of Motion Study (Micro-Motion Study (movie film) and the Chro- nocyclegraph) the Gilbreths were able to examine the smallest of motions. However, to make the

12/06/2016 · Efficiency Improvement Technique of Industrial Engineering Method study is production, service or business process improvement technique _____ Method study is the systematic recording and critical examination of ways of doing things in order to make improvements[1].

Contents VI 45 3.9 References 47 4 Motion economy 4.1 Principles ofmotioneconomy 47 4.2 Two-handedprocesschart 50 4.3 Micromotion study 4.4 Studyofmethodrecorded

Methods Engineering-Steps – Recording Tools and techniques – Design of work place layout – Motion study – micro motion study – THERBLINGs – cycle graph and chrono cycle graph – SIMO chart – Principles of motion economy.

The Industrial Engineering Terminology Standard defines Time study is a direct and continuous observation of a task, using a time keeping device e.g., decimal minute stopwatch, computer-assisted electronic stopwatch, and videotape camera to record the time taken to accomplish a task. The success of any mass production depends upon the interchangeability to facilitate easy assembly and

industrial engineering time motion pdf Industrial engineering is an inter-disciplinary profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integrated systems of

The word therblig was the creation of Frank Bunker Gilbreth and Lillian Moller Gilbreth, American industrial psychologists who invented the field of time and motion study. It is a reversal of the name Gilbreth , with ‘th’ transposed .

Mechanical and Industrial Engineering Our professionally based program features advanced study in thermofluids, manufacturing, materials, solid mechanics

He developed the micro motion study,i.e the subdivision of motion involved in the task.he develops Concept of fatigue in work, and efficency in work-methods 7. 1901 – Henry Gantt- Gantt chart main application solve scheduling problems.

§Work study improves industrial relations: l Workers feel that the management cares for them. l Workers discover that there are managers who highly understand their job. l Improving the feeling of confidence. l Workers are more able to carry out their jobs. October 03 Lotfi K. Gaafar 10 Work study and the Worker §Why workers resist the work study: l It will change their familiar work methods

Industrial Engineering can also assist by developing systems for maintaining methods and updating schedules. Motion economy and methods analysis are used by industrial engineering for effective use of capital.The man-made instruments of production – Materials,Machinery, and Facilities- can be analyzed trial engineering.By providing in the management and control of and-evaluated by this …

TIME & MOTION STUDY Issue Time & Motion Study TYPE TAGLINE HERE IN THIS ISSUE What A scientific method for collecting and analyzing work tasks in creating employee productivity standards and identifying all “hands-on time” while the entire work process to include, resources, layout, waiting, travel, walk away time, machine, and automation time are collected and documented. How A work …

industrial engineering groups, work simplification and value analysis programs, suggestion systems, quality circles, and other methods of achieving reduced costs of manufacturing their products. One of the consequences of these programs has been increased mechanization, which, in turn, has led to the production of more and more goods per work hour. Among the long-range benefits derived from

Work study, therefore, comprises of two areas of study: method study (motion study) and time study (work measurement). Role of Work Study in Improving Productivity In order to understand the role of work study, we need to understand the role of method study and that of time study.

Micro Motion Study Technique: Introduction, Definition, Purpose and Advantages! Introduction: Micro motion study technique is best suited for those operations or activities which are of short duration and which are repeated hundreds of time.

Frank Bunker Gilbreth Sr. Wikiquote

MEC441INDUSTRIAL ENGINEERING Abhijeet Kumar

Week 6: String Diagrams, Principles of Motion Economy, Micro-Motion Study, Therbligs, SIMO Charts Week 7: Memo-Motion Study, Cycle graph and Chrono-Cycle Graph, Critical Examination Techniques, Development and Selection of New Method, Installation and Maintenance of Improved Methods.

thermofluids, manufacturing, materials, solid mechanics, and industrial engineering. The student presents the project plan in writing, The student presents the project plan in writing, and the project is carried out under the guidance of the supervisor.

actually do and Gilbreths were charged with the task of proving that motion study particularly, and scientific management generally, increased industrial output in ways which improved and did not detract from workers’ mental and physical strength. ISSN: 2319-8753 International Journal of Innovative Research in Science, Engineering and Technology (ISO 3297: 2007 Certified Organization) Vol. 2

industrial engineering time motion pdf Industrial engineering is an inter-disciplinary profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integrated systems of

3 anna university, chennai affiliated institutions regulations 2017 m.e. industrial engineering choice based credit systems i to iv semesters (full time) curriculum and syllabus

12/06/2016 · Efficiency Improvement Technique of Industrial Engineering Method study is production, service or business process improvement technique _____ Method study is the systematic recording and critical examination of ways of doing things in order to make improvements[1].

Micro-motion devices technology The state of arts review

Gilbreth’s micromotion study Article about Gilbreth’s

Adopt this wiki Edit. This Industrial Engineering Wikia is currently inactive. If you would like to start a new Industrial Engineering wiki here, or revive the old one, please go ahead.

thermofluids, manufacturing, materials, solid mechanics, and industrial engineering. The student presents the project plan in writing, The student presents the project plan in writing, and the project is carried out under the guidance of the supervisor.

Time and Motion study D.S.S.C.P.Subasinghe E/04/288 Department of Mechanical Engineering Faculty of Engineering University of Peradeniya Time and Motion study What is time and motion study? This is a business efficiency technique. y d u t s em i •T Frederick W. Taylor and his followers developed and refined the Time Study. • Motion study Frank B. Gilbreth and his wife Lillian …

“Thus micro-motion study is the technique of recording and analysing the timing of basic elements of a operation with the objective of achieving the best method of performing the operation.”

WORK Analysis and Design Laboratory Manual Prepared by: Dr. Tamer Mohamed Ahmed Khalaf . 2 Department of Industrial Engineering College of Engineering King Saud University, KSA Preface This manual is intended for undergraduate industrial engineering students as well as for beginners in Work Analysis and Design. It provides the broad knowledge about the areas of methods, measurement, …

(industrial engineering) A time and motion study based on the concept that all work is performed by using a relatively few basic operations in varying combinations and sequence; basic elements (therbligs) include grasp, search, move, reach, and hold.

Micro motion and macro-motion study: Principles of motion economy. Employees provident fund scheme 1952. Work measurement techniques . sources of industrial finance. Payment of bonus act 1965. Factories act 1948. Quality assurance. variable and attributes.time 04 study. pre-determined motion time standards (PMTS) Determination of time standards. Industrial Engineering and …

Industrial engineering in apparel production GBV

Industrial Manufacturing and Systems Engineering Courses

Time and motion study impact the whole production rate of the company. Time and motion study is a method in order to determine the actual time needed to complete task. Problem Statement Time and motion study is the important aspect in business to determine the production rate. Another factor’s that effect the production rate is raw material, operation cost, work force and others. All this

10/05/2014 · INTRODUCTION: Definition of industrial engineering (IE), Development, applications, role of an industrial engineer, differences between production, management and industrial engineering, quantitative tools of IE and productivity measurement.

He developed the micro motion study,i.e the subdivision of motion involved in the task.he develops Concept of fatigue in work, and efficency in work-methods 7. 1901 – Henry Gantt- Gantt chart main application solve scheduling problems.

Some Techniques of Industrial Engineering •Measure – Time and Motion Study – Work Sampling • Control – Work Standards (Best Practices) – Accounting – Labor Reporting • Improve – Small group activities. Time Study • Observation –Sotp Wacth – Computer / Interactive • Engineering Labor Standards (Bad Idea) • Job Order / Labor reporting data. History • Frederick

The following points highlight the five main types of charts used in motion study. The types are: 1. Operation Process Chart 2. Flow Diagram 3.

actually do and Gilbreths were charged with the task of proving that motion study particularly, and scientific management generally, increased industrial output in ways which improved and did not detract from workers’ mental and physical strength. ISSN: 2319-8753 International Journal of Innovative Research in Science, Engineering and Technology (ISO 3297: 2007 Certified Organization) Vol. 2

Micro Motion Study Technique: Introduction, Definition, Purpose and Advantages! Introduction: Micro motion study technique is best suited for those operations or activities which are of short duration and which are repeated hundreds of time.

Micro motion and macro-motion study: Principles of motion economy. Employees provident fund scheme 1952. Work measurement techniques . sources of industrial finance. Payment of bonus act 1965. Factories act 1948. Quality assurance. variable and attributes.time 04 study. pre-determined motion time standards (PMTS) Determination of time standards. Industrial Engineering and …

“Thus micro-motion study is the technique of recording and analysing the timing of basic elements of a operation with the objective of achieving the best method of performing the operation.”

2/08/2016 · Download Motion and Time Study for Lean Manufacturing 3rd Edition Pdf Carrie. Loading… Unsubscribe from Carrie? Cancel Unsubscribe. Working… Subscribe Subscribed Unsubscribe 2. …

The important objectives of the motion study are: 1. To improve the process of doing work . 2. To improve the design of work place layout . 3. To find the best way of doing a job

Industrial Engineering FANDOM powered by Wikia

Evolution of Industrial Engineering ~ Mechanical Engineering

Industrial and Manufacturing Systems Engineering Theses and Dissertations . Follow Theses/Dissertations from 2018 PDF. The implication of rapid technologies on the design process, Esra’a Abdel-All. PDF. Adopting and incorporating crowdsourced traffic data in advanced transportation management systems, Mostafa Amin-Naseri. PDF. Solution methods and bounds for two-stage risk …

Micro motion study The main purpose of micro motion study was to calculate the overall human activity and these activities are further divided in to the small movements.

Products & Services: The Most Complete Portfolio in the Industry Emerson helps manufacturers achieve top quartile business performance through the industry’s broadest portfolio of technologies to measure, control, optimize and power their operations – and the experience and expertise to …

10/05/2014 · INTRODUCTION: Definition of industrial engineering (IE), Development, applications, role of an industrial engineer, differences between production, management and industrial engineering, quantitative tools of IE and productivity measurement.

thermofluids, manufacturing, materials, solid mechanics, and industrial engineering. The student presents the project plan in writing, The student presents the project plan in writing, and the project is carried out under the guidance of the supervisor.

2/08/2016 · Download Motion and Time Study for Lean Manufacturing 3rd Edition Pdf Carrie. Loading… Unsubscribe from Carrie? Cancel Unsubscribe. Working… Subscribe Subscribed Unsubscribe 2. …

He developed the micro motion study,i.e the subdivision of motion involved in the task.he develops Concept of fatigue in work, and efficency in work-methods 7. 1901 – Henry Gantt- Gantt chart main application solve scheduling problems.

28/10/2017 · Introduction to work and motion study, classification of charts and activity symbols, percentage utilization, micro motion study, standard & normal time …

Micro Motion Study Technique: Introduction, Definition, Purpose and Advantages! Introduction: Micro motion study technique is best suited for those operations or activities which are of short duration and which are repeated hundreds of time.

The Industrial Engineering Terminology Standard defines Time study is a direct and continuous observation of a task, using a time keeping device e.g., decimal minute stopwatch, computer-assisted electronic stopwatch, and videotape camera to record the time taken to accomplish a task. The success of any mass production depends upon the interchangeability to facilitate easy assembly and

Time and Motion Study Equipment A stop-watch Time study forms A study board Other Equipments: •Audio and Video Tape recorder • Stationary • Equipments related with particular field. Preparing for a Time Study The steps in the process studied must already be standardized; e.g. sequences have been determined. All the information about staff members should be available in library. Operator

Micro-Motion Study 9. Memo Motion Study 10. Cycle Graph and Chronocycle Graph 11. Critical Examination 12. Development and Selection of New Method 13. Principles of Motion Economy 14. Installation of the Proposed Method 15. Maintain the Proposed Method V. Work Measurement : 1. Definition 2. Objectives of Work Measurement 3. Techniques of Work Measurement 4. Types of Elements 5. Time Study

The word therblig was the creation of Frank Bunker Gilbreth and Lillian Moller Gilbreth, American industrial psychologists who invented the field of time and motion study. It is a reversal of the name Gilbreth , with ‘th’ transposed .

(industrial engineering) A time and motion study based on the concept that all work is performed by using a relatively few basic operations in varying combinations and sequence; basic elements (therbligs) include grasp, search, move, reach, and hold.

12/06/2016 · Principles of Motion Economy As Related to the Design of Tools and Equipment 18. The hands should be relieved of all work that can be done more advantageously by a jig, a fixture, or a foot-operated device.

Time and Motion Study Equipment A stop-watch Time study forms A study board Other Equipments: •Audio and Video Tape recorder • Stationary • Equipments related with particular field. Preparing for a Time Study The steps in the process studied must already be standardized; e.g. sequences have been determined. All the information about staff members should be available in library. Operator

Industrial and Manufacturing Systems Engineering Theses