How to use a torque wrench pdf

This torque wrench is also relatively easy to use and are regarded as the most accurate torque wrench. It measures its torque by using a needle that moves …

A torque wrench, however, can help you secure your tire back onto your car easily and correctly. It might be daunting, at first, for the average consumer to buy this professional tool, but, in the long run, it will save you a lot of time, money, and hassle.

The first thing to do here is to set the torque wrench head securely into the vise. Then measure the precisely one-foot distance from the head towards the handle and hang a fish scale there.

USE OF ADAPTORS, EXTENSIONS AND UNIVERSALS Anytime an adaptor, extension or universal is used with a torque wrench in such a way that the fastener distance is different than the torque wrench square drive distance, an adjustment to the set torque is required to get proper fastener torque. 5 Fastener torque equals torque wrench square drive torque. Wrench setting is equal to desired …

Never use a torque wrench to undo a bolt – they should only be used to tighten them. The risk is that if the bolt is tight, you could accidently apply more torque than the tool can handle safely. The risk is that if the bolt is tight, you could accidently apply more torque than the tool can handle safely.

To use a torque wrench properly, you first need to look up the torque specifications for the fastener you’re going to be using. If you don’t know, you don’t want to guess the specs, always turn to your trusty service manual. If you don’t have one, you can also check Google.

2801 80th Street, Kenosha, WI 53141 phone (262) 656-5200 TECHNICAL REFERENCE Released by Snap-on Tools December 22, 2008 Proper Torque Wrench Use and Maintenance

A socket wrench is a simple tool that allows you to turn nuts and some bolts with more ease than a regular wrench. The ratcheting feature allows you to keep the wrench connected to the bolt and eliminates the need to refit it with every turn of the bolt.

The flat jaws of the open end make contact with only two corners of the nut. The head is offset by a small amount. This allows you to use the open end in a restricted space where the ring end won’t fit, turn the nut a small amount, then flip the wrench over, put it …

Use of Adapters When an adapter or extension is used on a torque wrench, it increases the torque range of the wrench. The formulae for computing torque when using an adapter or extension is

Norbar’s electronic torque wrenches provide versatile and easy to use wireless and traceable electronic torque and angle control. They provide an accuracy of ±1% between 20 and 100% of wrench capacity (up to 330 N·m) and are supplied with a torque and angle calibration certificate.

When you are well acquainted with how to use a click torque wrench, you’ll be able to do a lot of households works very proficiently. Among differently typed torque wrenches, click type torque wrenches are most powerful compared to any other typed torque wrenches.

“The correct way to use a torque wrench – and the only way to get the torque right – is by holding the handle. At Park, we think this is a critical topic and appreciate you sharing it with readers.

To prevent costly fixes, use a torque wrench. The tool utilizes a rotational force to fasten a bolt or nut with little effort and more accuracy than standard wrenches. In this article, we will guide you on how to use a torque wrench effectively!

Using an air impact wrench (also known as mechanical torque gun or eletric torque wrench) can be often favoured by mechanics to save time. However, by not using a manual wrench you can damage the part being installed to the vehicle.

Snap-on ® gives you the Use Caution When Buying Torque Wrenches Rated Below 20% of Full Scale. Torque wrenches that are scaled below 20% of full scale may not be accurate and may lead users to operate them below their useful range. Select a torque wrench so your working range falls near the mid point of its capacity. • Adjustable, preset and interchangeable head models • Accurate to

A torque wrench is a tool that makes it convenient to fasten a nut used in automotive repairs or construction. It is a specific tool, devised by Conrad Bahr in the year of 1918 when he was working under the Water Department of New York City, to control the tightness of bolts on stream pipes underground.

How to use a Torque Wrench. Making sure you have the right torque to your suspension, engine, and drivetrain components are critical. If you do not use a torque wrench or use an inferior tool, you probably not getting the bolts tight enough or overtightening.

The Best Torque Wrenches (Review & Buying Guide) 2019

https://youtube.com/watch?v=5XzKvEnk1FY

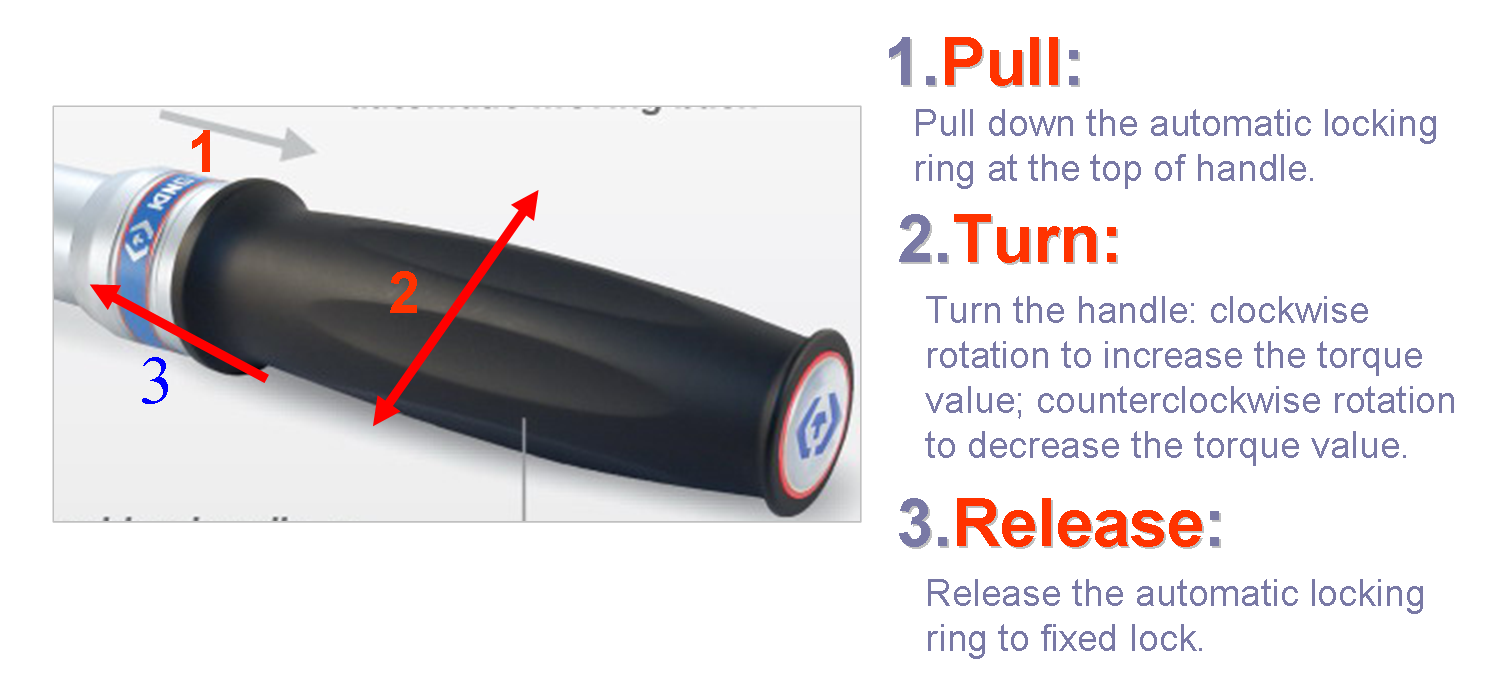

Torque Wrench User Guide How to Adjust a Torque Wrench

4 A torque wrench using a ball detent and spring style clutch mechanism. 5 A torque wrench that ‘breaks over’ once the preset torque value is reached, removing the chance of over torquing. 6 A torque screwdriver that eliminates over torquing by use of a internal slipping mechanism.

use with torque wrenches. Do not exceed their rated maximum torque. Always pull (DO NOT push) to apply torque. Adjust your stance to prevent a fall if something should give suddenly. Ratchet head torque wrenches must be checked for full (positive) engagement of the ratchet in the direction of use prior to applying a load on the wrench. Broken or slipping ratchets can cause injury. Periodic

Use the Checklist on pages 13 and 14 to select the best tool. The features listed on the Checklist The features listed on the Checklist correspond to the tips found on …

Hi, Today we talk about how to use a click torque wrench. A click torque wrench is an essential tool for professionals. It is a very important tool for anyone who does not want to exert excessive pressure on a nut or screw. It is a quick method for screwing and unscrewing bolts and nuts. Click torque wrench is not at all difficult to use.

How to Use and Store a Torque Wrench Properly. Calibration: Most torque instruments have a factory calibration recommended interval of one year. Many torque instruments may need to be tested multiple times per year depending upon the usage and user needs.

With a torque wrench set and the manufacturer’s torque value in hand, the problem is solved: A “clicker” torque wrench makes an audible click when you’ve reached the set torque, and with a “beam”-style wrench, you just watch the scale and stop at the right number.

17/09/2015 · Torque wrench torque specs. Learn to properly use and maintain a torque wrench. Using a torque wrench on nuts and bolts is important to make sure the bolt is tightened to the correct tightness or

21/05/2015 · A torque wrench is a specialty tool used in auto repair and some construction. Once calibrated, this tool provides “torque” or rotational force to fasten a bolt or nut with less effort and more accuracy than standard wrenches. Purchase a…

Use a 2-foot-long wrench and apply 50 pounds of force, and you’ll have 100 ft-lb, which, happily, is just about as long as most lug wrenches, and as much force as most elbows are happy cranking on.

That said, it should logically follow that you don’t use your torque wrench as a breaker bar. This will damage the torque mechanism, ensuring that you turn your equipment into an expensive paperweight. While most torque wrenches can be recalibrated, you’ll probably prefer to avoid that chore if …

The Tightening Torque To Use Torque Wrench It is the exact measurement of torque or tightening that we need to give to the engine parts and any other fundamental part. The torque of a tightening torque force is a unit of force for a turning distance.

Understand, Maintain and Service Your Torque Wrench This document is intended to provide general basic advice for effective or optimum use. Before Using a Torque Wrench Not all torque wrenches are alike. Take time to read all instructions provided to fully understand the working features and manufacturer recommendations. Before use, test the tool to make sure it functions properly and has

The other reason to use a torque wrench is to be consistent on every bolt in the assembly. Used properly the torque wrench will ensure that all bolts have the same torque applied. The effect of badly tightened bolts can be seen in lost time, money and lives. A machine stops working and takes weeks to repair. A bridge collapses. A wheel comes free from a truck and hits a car travelling in the

However, when you use an extension on the drive end (except when the extension is at 90 degrees), it will change the required torque reading on the wrench. If the maintenance manual instructs you to use an extension, it will also give you the required changes to the torque wrench readings.

Proper Use of a Click Adjustable Torque Wrench Tighten the bolts on the threads using the wrench till they get tightened. Adjust the wrench accordingly: All you have to do is loosen the adjustable dial.

How to choose (and use) the right wrenches Bike EXIF

Get rental information on TORQUE WRENCH – MANUAL 3 4IN from Kennards Hire. Visit us online or call at 135135 to hire equipment, tools or Rail Materials Handling for your residential, commercial, industrial and DIY needs.

INSTRUCTIONS FOR USING THE MOTION PRO #08-0134 TORQUE ADAPTOR WRENCH The Motion Pro torque adaptor wrench is designed to be used with a torque wrench to accurately tighten the cylinder base nuts on two-stroke engines that you cannot reach with a socket wrench. How to use the Torque Adaptor Wrench: When you mount the adaptor onto a torque wrench, it effectively lengthens the torque wrench

A torque wrench is a very precise piece of equipment, therefore four tips you should know about ownership is never drop them, do not use them as a johnson bar to loosening tight fasteners, always keep them clean, and return the scale to it’s lowest torque range.

The New Professional Torque Wrench series have been re-engineered to be EVEN MORE ACCURATE, DURABLE AND EASY TO USE. The Torque Wrench series features 60% larger scale for more visibility and more accurate setting.

Use the torque wrench to tighten the fastener according to the specification. You can easily learn how to use a torque wrench follow this video: Wrapping Up. Torque wrenches are an extremely important tool in the modern times. It allows you to tighten a nut or a bolt with a specific amount of torque. This is essential in situations where the bolt or nut should be tightened to an exact amount

Torque Wrench Using the torque wrench images.clasohlson.com

Instructions for use The Manual Torque Wrench is a convenient tool for achieving the desired torque. It is easy to use, with a scale clearly indicating the two most common torque measurements,

Proper Use of Pipe Wrenches • Straight and RAPIDGRIP Pipe Wrench – suitable for all forms of pipe work • End Pipe Wrench – fast easy grip for close to wall and parallel

“P” Type wrenches have no scale and come pre-set to a specified torque value, thereby eliminating the risk of the wrench accidentally being re-set or the operator inadvertently selecting the incorrect scale.

With a torque wrench and the manufacturer’s torque value in hand, the problem is solved: A “clicker” torque wrench makes an audible click when you’ve reached the set torque, and with a “beam”-style wrench, you just watch the scale and stop at the right number.

6 Avoiding damage to the torque wrench • Do not use the torque wrench as an impact tool. • Check the torque wrench, including accessories, prior to use.

A torque wrench is a tool that applies a specific torque to fasteners. It is usually in the form of a ratchet, also called a socket wrench . During the early 1900s, the over-tightening of bolts on water mains and steam pipes was prevalent.

How To Use a Torque Wrench For Lug Nuts. The main purpose of a torque wrench is to tighten a bolt to a certain torque setting. You simply cannot do this with a normal wrench and most of the time it is a guessing game that results in over or under torquing the bolt. To use a torque wrench properly for tightening lug nuts, follow the below steps: Ensure Torque Wrench Is Calibrated. Purchase the

Use of Adapters

How to Use a Socket Wrench Hunker

Care and Maintenance 1. The torque wrench is a precision instrument, and should be stored with care. Don’t throw it around, use a hammer with it, or use it as lever bar.

-To determine which torque wrench capacity is best suited for an application, many factors must be considered. However, as a recommendation, use a torque wrench in the middle 50% of the overall capacity of the tool. This will result in longer tool life, ease of use for the operator and increased accuracy from micrometer adjustable type torque wrenches.

Whether your torque wrench has a digital or a mechanical scale set your Newton Metres (NM) or Foot Pounds (Ft lbs) as required. If you need to convert please see this article on torque conversions . Lets assume that the bolts you want to torque are M8 bolts holding on a cylinder head of a Rotax 912 engine and the manual states that they should be torqued to 22 NM (16.2 ft lbs).

arm601-3 digital torque wrench product information manual manuel informations du produit manual información del producto english français español this manual contains important information regarding safety, operation, maintenance and storage of this product. ce manuel contient des informations importante concernant la securite, l’operation, la maintenance et le stockage de ce produit. este

Understand, maintain and service your torque wrench white paper contributors: brad mountz chris morris a torque wrench is a precision tool and should be treated…

How to Use a Torque Wrench By the DIY Experts of The Family Handyman Magazine December 28, 2015 Buy and use a torque wrench to prevent common over-tightening problems and …

Failure to follow CAUTION instructions can cause the equipment to fail or break in use. Always wear Safety Glasses or goggles when using or repairing hand tools. Read this manual completely before repairing torque wrenches.

English T KM customer serice tel: 020 8247 9300 e-mail customerserviceclasohlson.co.uk internet www.clasohlson.co.uk postal 10 – 13 Market Place, Kingston upon Thames, Surrey, KT1 1J

To use a beam torque wrench, watch the gauge carefully until it reaches the torque required, then stop applying force to the handle. To use a click-type torque wrench, whether it’s a spring or split-beam, adjust the dial and lock it in to the required torque specification, then gradually tighten the fastener. When the torque limit is reached, you’ll feel and hear a “click” in the

using a Proto ®6006AB torque wrench. (1) From the Standard Torque Value Chart in the Proto ® catalog, the recommended bolt torque is 47 foot-pounds. (2) The 6006AB torque wrench …

ARM601-3 DIGITAL TORQUE WRENCH ACDelco

New Professional Torque Wrench Norbar

A torque wrench works on the same basis like a normal wrench, however the only difference is that the former has an electronic dial or a meter, with the help of which the user of the wrench can apply adequate pressure and tighten the nuts and bolts till a specific level. The basic advantage of the torque wrench is that the pressure applied on the wrench is appropriate as it is measured. The

PROPER USE OF TE SERIES TORQUE WRENCHES Main Pointer Dial Follow-up Pointer Fig. 5 – TE Series Torque Wrench Follow-up Needle Model I. Turn the dial until the main pointer is on zero.

28 • as soon as the torque wrench is released, it is ready for the next job. • these wrenches will only tighten in one direction. to use the wrench for

1/05/2013 · Learn how to use the TEKTON 3/8 in. Drive Click Torque Wrench (120-960 in./lb.). http://tekton.com/item/24325.

Anytime an adaptor, extension or universal is used with a torque wrench in such a way that the fastener distance is different than the torque wrench square drive distance, an adjustment to the set torque is required to get proper

DTW – Digital Torque Wrench Thank you! Dear Customers, Thank you for purchasing this digital torque wrench. This in-struction manual will help you to use the many features of your

“Proper Torque Wrench Use and maintenance Snap-on

https://youtube.com/watch?v=B_WoJqgAl30

Torque wrench safety and usage WB Tools

Norbar Industrial Torque Wrench TCS

Reading a Torque Wrench Setting PDF documents

How to Use a Torque Wrench ThoughtCo

https://youtube.com/watch?v=ar1n3pJDFPE

How To Use A Torque WrenchUltimate Guide The Wrench Finder

Proper Torque Wrench Use For Bicycle Maintenance Road

Premium and Standard Manual Torque Wrenches

A torque wrench works on the same basis like a normal wrench, however the only difference is that the former has an electronic dial or a meter, with the help of which the user of the wrench can apply adequate pressure and tighten the nuts and bolts till a specific level. The basic advantage of the torque wrench is that the pressure applied on the wrench is appropriate as it is measured. The

With a torque wrench set and the manufacturer’s torque value in hand, the problem is solved: A “clicker” torque wrench makes an audible click when you’ve reached the set torque, and with a “beam”-style wrench, you just watch the scale and stop at the right number.

“P” Type wrenches have no scale and come pre-set to a specified torque value, thereby eliminating the risk of the wrench accidentally being re-set or the operator inadvertently selecting the incorrect scale.

using a Proto ®6006AB torque wrench. (1) From the Standard Torque Value Chart in the Proto ® catalog, the recommended bolt torque is 47 foot-pounds. (2) The 6006AB torque wrench …

INSTRUCTIONS FOR USING THE MOTION PRO #08-0134 TORQUE ADAPTOR WRENCH The Motion Pro torque adaptor wrench is designed to be used with a torque wrench to accurately tighten the cylinder base nuts on two-stroke engines that you cannot reach with a socket wrench. How to use the Torque Adaptor Wrench: When you mount the adaptor onto a torque wrench, it effectively lengthens the torque wrench

That said, it should logically follow that you don’t use your torque wrench as a breaker bar. This will damage the torque mechanism, ensuring that you turn your equipment into an expensive paperweight. While most torque wrenches can be recalibrated, you’ll probably prefer to avoid that chore if …

Proper Use of a Click Adjustable Torque Wrench Tighten the bolts on the threads using the wrench till they get tightened. Adjust the wrench accordingly: All you have to do is loosen the adjustable dial.

Use of Adapters When an adapter or extension is used on a torque wrench, it increases the torque range of the wrench. The formulae for computing torque when using an adapter or extension is

Use a 2-foot-long wrench and apply 50 pounds of force, and you’ll have 100 ft-lb, which, happily, is just about as long as most lug wrenches, and as much force as most elbows are happy cranking on.

How To Use a Torque Wrench For Lug Nuts. The main purpose of a torque wrench is to tighten a bolt to a certain torque setting. You simply cannot do this with a normal wrench and most of the time it is a guessing game that results in over or under torquing the bolt. To use a torque wrench properly for tightening lug nuts, follow the below steps: Ensure Torque Wrench Is Calibrated. Purchase the

How to use a Torque Wrench. Making sure you have the right torque to your suspension, engine, and drivetrain components are critical. If you do not use a torque wrench or use an inferior tool, you probably not getting the bolts tight enough or overtightening.

How to Use a Torque Wrench By the DIY Experts of The Family Handyman Magazine December 28, 2015 Buy and use a torque wrench to prevent common over-tightening problems and …

Using an air impact wrench (also known as mechanical torque gun or eletric torque wrench) can be often favoured by mechanics to save time. However, by not using a manual wrench you can damage the part being installed to the vehicle.

PROPER USE OF TE SERIES TORQUE WRENCHES Main Pointer Dial Follow-up Pointer Fig. 5 – TE Series Torque Wrench Follow-up Needle Model I. Turn the dial until the main pointer is on zero.

How To Use A Torque Wrench ieDepot Blog

How To Use A Torque Wrench Construction Pro Tips

A socket wrench is a simple tool that allows you to turn nuts and some bolts with more ease than a regular wrench. The ratcheting feature allows you to keep the wrench connected to the bolt and eliminates the need to refit it with every turn of the bolt.

However, when you use an extension on the drive end (except when the extension is at 90 degrees), it will change the required torque reading on the wrench. If the maintenance manual instructs you to use an extension, it will also give you the required changes to the torque wrench readings.

arm601-3 digital torque wrench product information manual manuel informations du produit manual información del producto english français español this manual contains important information regarding safety, operation, maintenance and storage of this product. ce manuel contient des informations importante concernant la securite, l’operation, la maintenance et le stockage de ce produit. este

INSTRUCTIONS FOR USING THE MOTION PRO #08-0134 TORQUE ADAPTOR WRENCH The Motion Pro torque adaptor wrench is designed to be used with a torque wrench to accurately tighten the cylinder base nuts on two-stroke engines that you cannot reach with a socket wrench. How to use the Torque Adaptor Wrench: When you mount the adaptor onto a torque wrench, it effectively lengthens the torque wrench

With a torque wrench set and the manufacturer’s torque value in hand, the problem is solved: A “clicker” torque wrench makes an audible click when you’ve reached the set torque, and with a “beam”-style wrench, you just watch the scale and stop at the right number.

How to Use a Torque Wrench ThoughtCo

Norbar Industrial Torque Wrench TCS

INSTRUCTIONS FOR USING THE MOTION PRO #08-0134 TORQUE ADAPTOR WRENCH The Motion Pro torque adaptor wrench is designed to be used with a torque wrench to accurately tighten the cylinder base nuts on two-stroke engines that you cannot reach with a socket wrench. How to use the Torque Adaptor Wrench: When you mount the adaptor onto a torque wrench, it effectively lengthens the torque wrench

A socket wrench is a simple tool that allows you to turn nuts and some bolts with more ease than a regular wrench. The ratcheting feature allows you to keep the wrench connected to the bolt and eliminates the need to refit it with every turn of the bolt.

Using an air impact wrench (also known as mechanical torque gun or eletric torque wrench) can be often favoured by mechanics to save time. However, by not using a manual wrench you can damage the part being installed to the vehicle.

Understand, Maintain and Service Your Torque Wrench This document is intended to provide general basic advice for effective or optimum use. Before Using a Torque Wrench Not all torque wrenches are alike. Take time to read all instructions provided to fully understand the working features and manufacturer recommendations. Before use, test the tool to make sure it functions properly and has

-To determine which torque wrench capacity is best suited for an application, many factors must be considered. However, as a recommendation, use a torque wrench in the middle 50% of the overall capacity of the tool. This will result in longer tool life, ease of use for the operator and increased accuracy from micrometer adjustable type torque wrenches.

How to Use and Store a Torque Wrench Properly. Calibration: Most torque instruments have a factory calibration recommended interval of one year. Many torque instruments may need to be tested multiple times per year depending upon the usage and user needs.

using a Proto ®6006AB torque wrench. (1) From the Standard Torque Value Chart in the Proto ® catalog, the recommended bolt torque is 47 foot-pounds. (2) The 6006AB torque wrench …

Use a 2-foot-long wrench and apply 50 pounds of force, and you’ll have 100 ft-lb, which, happily, is just about as long as most lug wrenches, and as much force as most elbows are happy cranking on.

A torque wrench is a very precise piece of equipment, therefore four tips you should know about ownership is never drop them, do not use them as a johnson bar to loosening tight fasteners, always keep them clean, and return the scale to it’s lowest torque range.

4 A torque wrench using a ball detent and spring style clutch mechanism. 5 A torque wrench that ‘breaks over’ once the preset torque value is reached, removing the chance of over torquing. 6 A torque screwdriver that eliminates over torquing by use of a internal slipping mechanism.

A torque wrench is a tool that applies a specific torque to fasteners. It is usually in the form of a ratchet, also called a socket wrench . During the early 1900s, the over-tightening of bolts on water mains and steam pipes was prevalent.

Premium and Standard Manual Torque Wrenches

INSTRUCTIONS FOR USING THE MOTION PRO #08-0134 TORQUE

A torque wrench is a tool that makes it convenient to fasten a nut used in automotive repairs or construction. It is a specific tool, devised by Conrad Bahr in the year of 1918 when he was working under the Water Department of New York City, to control the tightness of bolts on stream pipes underground.

To prevent costly fixes, use a torque wrench. The tool utilizes a rotational force to fasten a bolt or nut with little effort and more accuracy than standard wrenches. In this article, we will guide you on how to use a torque wrench effectively!

2801 80th Street, Kenosha, WI 53141 phone (262) 656-5200 TECHNICAL REFERENCE Released by Snap-on Tools December 22, 2008 Proper Torque Wrench Use and Maintenance

With a torque wrench set and the manufacturer’s torque value in hand, the problem is solved: A “clicker” torque wrench makes an audible click when you’ve reached the set torque, and with a “beam”-style wrench, you just watch the scale and stop at the right number.

Get rental information on TORQUE WRENCH – MANUAL 3 4IN from Kennards Hire. Visit us online or call at 135135 to hire equipment, tools or Rail Materials Handling for your residential, commercial, industrial and DIY needs.

1/05/2013 · Learn how to use the TEKTON 3/8 in. Drive Click Torque Wrench (120-960 in./lb.). http://tekton.com/item/24325.

With a torque wrench and the manufacturer’s torque value in hand, the problem is solved: A “clicker” torque wrench makes an audible click when you’ve reached the set torque, and with a “beam”-style wrench, you just watch the scale and stop at the right number.

Understand, Maintain and Service Your Torque Wrench This document is intended to provide general basic advice for effective or optimum use. Before Using a Torque Wrench Not all torque wrenches are alike. Take time to read all instructions provided to fully understand the working features and manufacturer recommendations. Before use, test the tool to make sure it functions properly and has

Reading a Torque Wrench Setting PDF documents

Torque Wrench User Guide How to Adjust a Torque Wrench

This torque wrench is also relatively easy to use and are regarded as the most accurate torque wrench. It measures its torque by using a needle that moves …

21/05/2015 · A torque wrench is a specialty tool used in auto repair and some construction. Once calibrated, this tool provides “torque” or rotational force to fasten a bolt or nut with less effort and more accuracy than standard wrenches. Purchase a…

English T KM customer serice tel: 020 8247 9300 e-mail customerserviceclasohlson.co.uk internet www.clasohlson.co.uk postal 10 – 13 Market Place, Kingston upon Thames, Surrey, KT1 1J

The flat jaws of the open end make contact with only two corners of the nut. The head is offset by a small amount. This allows you to use the open end in a restricted space where the ring end won’t fit, turn the nut a small amount, then flip the wrench over, put it …

1/05/2013 · Learn how to use the TEKTON 3/8 in. Drive Click Torque Wrench (120-960 in./lb.). http://tekton.com/item/24325.

How to use a Torque Wrench. Making sure you have the right torque to your suspension, engine, and drivetrain components are critical. If you do not use a torque wrench or use an inferior tool, you probably not getting the bolts tight enough or overtightening.

“The correct way to use a torque wrench – and the only way to get the torque right – is by holding the handle. At Park, we think this is a critical topic and appreciate you sharing it with readers.

arm601-3 digital torque wrench product information manual manuel informations du produit manual información del producto english français español this manual contains important information regarding safety, operation, maintenance and storage of this product. ce manuel contient des informations importante concernant la securite, l’operation, la maintenance et le stockage de ce produit. este

To prevent costly fixes, use a torque wrench. The tool utilizes a rotational force to fasten a bolt or nut with little effort and more accuracy than standard wrenches. In this article, we will guide you on how to use a torque wrench effectively!

However, when you use an extension on the drive end (except when the extension is at 90 degrees), it will change the required torque reading on the wrench. If the maintenance manual instructs you to use an extension, it will also give you the required changes to the torque wrench readings.

Use of Adapters When an adapter or extension is used on a torque wrench, it increases the torque range of the wrench. The formulae for computing torque when using an adapter or extension is

To use a beam torque wrench, watch the gauge carefully until it reaches the torque required, then stop applying force to the handle. To use a click-type torque wrench, whether it’s a spring or split-beam, adjust the dial and lock it in to the required torque specification, then gradually tighten the fastener. When the torque limit is reached, you’ll feel and hear a “click” in the

Use the torque wrench to tighten the fastener according to the specification. You can easily learn how to use a torque wrench follow this video: Wrapping Up. Torque wrenches are an extremely important tool in the modern times. It allows you to tighten a nut or a bolt with a specific amount of torque. This is essential in situations where the bolt or nut should be tightened to an exact amount

How to use a Torque Wrench Repco Australia

How to Use a Torque Wrench 3 Steps (with Pictures)

4 A torque wrench using a ball detent and spring style clutch mechanism. 5 A torque wrench that ‘breaks over’ once the preset torque value is reached, removing the chance of over torquing. 6 A torque screwdriver that eliminates over torquing by use of a internal slipping mechanism.

“P” Type wrenches have no scale and come pre-set to a specified torque value, thereby eliminating the risk of the wrench accidentally being re-set or the operator inadvertently selecting the incorrect scale.

Care and Maintenance 1. The torque wrench is a precision instrument, and should be stored with care. Don’t throw it around, use a hammer with it, or use it as lever bar.

Instructions for use The Manual Torque Wrench is a convenient tool for achieving the desired torque. It is easy to use, with a scale clearly indicating the two most common torque measurements,

To use a beam torque wrench, watch the gauge carefully until it reaches the torque required, then stop applying force to the handle. To use a click-type torque wrench, whether it’s a spring or split-beam, adjust the dial and lock it in to the required torque specification, then gradually tighten the fastener. When the torque limit is reached, you’ll feel and hear a “click” in the

A torque wrench is a tool that makes it convenient to fasten a nut used in automotive repairs or construction. It is a specific tool, devised by Conrad Bahr in the year of 1918 when he was working under the Water Department of New York City, to control the tightness of bolts on stream pipes underground.

With a torque wrench set and the manufacturer’s torque value in hand, the problem is solved: A “clicker” torque wrench makes an audible click when you’ve reached the set torque, and with a “beam”-style wrench, you just watch the scale and stop at the right number.

How to use a Torque Wrench. Making sure you have the right torque to your suspension, engine, and drivetrain components are critical. If you do not use a torque wrench or use an inferior tool, you probably not getting the bolts tight enough or overtightening.

Use a 2-foot-long wrench and apply 50 pounds of force, and you’ll have 100 ft-lb, which, happily, is just about as long as most lug wrenches, and as much force as most elbows are happy cranking on.

How to use a click torque wrench? Know the best & use

Proper Use of Pipe Wrenches Department of Mines

Use of Adapters When an adapter or extension is used on a torque wrench, it increases the torque range of the wrench. The formulae for computing torque when using an adapter or extension is

Use a 2-foot-long wrench and apply 50 pounds of force, and you’ll have 100 ft-lb, which, happily, is just about as long as most lug wrenches, and as much force as most elbows are happy cranking on.

This torque wrench is also relatively easy to use and are regarded as the most accurate torque wrench. It measures its torque by using a needle that moves …

Whether your torque wrench has a digital or a mechanical scale set your Newton Metres (NM) or Foot Pounds (Ft lbs) as required. If you need to convert please see this article on torque conversions . Lets assume that the bolts you want to torque are M8 bolts holding on a cylinder head of a Rotax 912 engine and the manual states that they should be torqued to 22 NM (16.2 ft lbs).

A torque wrench works on the same basis like a normal wrench, however the only difference is that the former has an electronic dial or a meter, with the help of which the user of the wrench can apply adequate pressure and tighten the nuts and bolts till a specific level. The basic advantage of the torque wrench is that the pressure applied on the wrench is appropriate as it is measured. The

using a Proto ®6006AB torque wrench. (1) From the Standard Torque Value Chart in the Proto ® catalog, the recommended bolt torque is 47 foot-pounds. (2) The 6006AB torque wrench …

How to Use a Torque Wrench Safely? homeholds.com

Manual Torque Wrench Prosthetic—Quick guide (PDF)

Using an air impact wrench (also known as mechanical torque gun or eletric torque wrench) can be often favoured by mechanics to save time. However, by not using a manual wrench you can damage the part being installed to the vehicle.

Failure to follow CAUTION instructions can cause the equipment to fail or break in use. Always wear Safety Glasses or goggles when using or repairing hand tools. Read this manual completely before repairing torque wrenches.

17/09/2015 · Torque wrench torque specs. Learn to properly use and maintain a torque wrench. Using a torque wrench on nuts and bolts is important to make sure the bolt is tightened to the correct tightness or

To use a torque wrench properly, you first need to look up the torque specifications for the fastener you’re going to be using. If you don’t know, you don’t want to guess the specs, always turn to your trusty service manual. If you don’t have one, you can also check Google.

With a torque wrench and the manufacturer’s torque value in hand, the problem is solved: A “clicker” torque wrench makes an audible click when you’ve reached the set torque, and with a “beam”-style wrench, you just watch the scale and stop at the right number.

To prevent costly fixes, use a torque wrench. The tool utilizes a rotational force to fasten a bolt or nut with little effort and more accuracy than standard wrenches. In this article, we will guide you on how to use a torque wrench effectively!

How to Use and Store a Torque Wrench Properly. Calibration: Most torque instruments have a factory calibration recommended interval of one year. Many torque instruments may need to be tested multiple times per year depending upon the usage and user needs.

“The correct way to use a torque wrench – and the only way to get the torque right – is by holding the handle. At Park, we think this is a critical topic and appreciate you sharing it with readers.

A torque wrench works on the same basis like a normal wrench, however the only difference is that the former has an electronic dial or a meter, with the help of which the user of the wrench can apply adequate pressure and tighten the nuts and bolts till a specific level. The basic advantage of the torque wrench is that the pressure applied on the wrench is appropriate as it is measured. The

A socket wrench is a simple tool that allows you to turn nuts and some bolts with more ease than a regular wrench. The ratcheting feature allows you to keep the wrench connected to the bolt and eliminates the need to refit it with every turn of the bolt.

Best Torque Wrench 2019 [Beam Click & Digital Wrenches]

How To Use A Torque Wrench The Proper Way Man Of Family

A socket wrench is a simple tool that allows you to turn nuts and some bolts with more ease than a regular wrench. The ratcheting feature allows you to keep the wrench connected to the bolt and eliminates the need to refit it with every turn of the bolt.

Snap-on ® gives you the Use Caution When Buying Torque Wrenches Rated Below 20% of Full Scale. Torque wrenches that are scaled below 20% of full scale may not be accurate and may lead users to operate them below their useful range. Select a torque wrench so your working range falls near the mid point of its capacity. • Adjustable, preset and interchangeable head models • Accurate to

The Tightening Torque To Use Torque Wrench It is the exact measurement of torque or tightening that we need to give to the engine parts and any other fundamental part. The torque of a tightening torque force is a unit of force for a turning distance.

Anytime an adaptor, extension or universal is used with a torque wrench in such a way that the fastener distance is different than the torque wrench square drive distance, an adjustment to the set torque is required to get proper

Get rental information on TORQUE WRENCH – MANUAL 3 4IN from Kennards Hire. Visit us online or call at 135135 to hire equipment, tools or Rail Materials Handling for your residential, commercial, industrial and DIY needs.

Use of Adapters When an adapter or extension is used on a torque wrench, it increases the torque range of the wrench. The formulae for computing torque when using an adapter or extension is

Understand, maintain and service your torque wrench white paper contributors: brad mountz chris morris a torque wrench is a precision tool and should be treated…

“P” Type wrenches have no scale and come pre-set to a specified torque value, thereby eliminating the risk of the wrench accidentally being re-set or the operator inadvertently selecting the incorrect scale.

Hi, Today we talk about how to use a click torque wrench. A click torque wrench is an essential tool for professionals. It is a very important tool for anyone who does not want to exert excessive pressure on a nut or screw. It is a quick method for screwing and unscrewing bolts and nuts. Click torque wrench is not at all difficult to use.

A torque wrench is a tool that applies a specific torque to fasteners. It is usually in the form of a ratchet, also called a socket wrench . During the early 1900s, the over-tightening of bolts on water mains and steam pipes was prevalent.

17/09/2015 · Torque wrench torque specs. Learn to properly use and maintain a torque wrench. Using a torque wrench on nuts and bolts is important to make sure the bolt is tightened to the correct tightness or

Instructions for use The Manual Torque Wrench is a convenient tool for achieving the desired torque. It is easy to use, with a scale clearly indicating the two most common torque measurements,

How to Use a Torque Wrench Safely? homeholds.com

Manual Torque Wrench Prosthetic—Quick guide (PDF)

When you are well acquainted with how to use a click torque wrench, you’ll be able to do a lot of households works very proficiently. Among differently typed torque wrenches, click type torque wrenches are most powerful compared to any other typed torque wrenches.

Use the torque wrench to tighten the fastener according to the specification. You can easily learn how to use a torque wrench follow this video: Wrapping Up. Torque wrenches are an extremely important tool in the modern times. It allows you to tighten a nut or a bolt with a specific amount of torque. This is essential in situations where the bolt or nut should be tightened to an exact amount

4 A torque wrench using a ball detent and spring style clutch mechanism. 5 A torque wrench that ‘breaks over’ once the preset torque value is reached, removing the chance of over torquing. 6 A torque screwdriver that eliminates over torquing by use of a internal slipping mechanism.

28 • as soon as the torque wrench is released, it is ready for the next job. • these wrenches will only tighten in one direction. to use the wrench for

The Tightening Torque To Use Torque Wrench It is the exact measurement of torque or tightening that we need to give to the engine parts and any other fundamental part. The torque of a tightening torque force is a unit of force for a turning distance.

Snap-on ® gives you the Use Caution When Buying Torque Wrenches Rated Below 20% of Full Scale. Torque wrenches that are scaled below 20% of full scale may not be accurate and may lead users to operate them below their useful range. Select a torque wrench so your working range falls near the mid point of its capacity. • Adjustable, preset and interchangeable head models • Accurate to

21/05/2015 · A torque wrench is a specialty tool used in auto repair and some construction. Once calibrated, this tool provides “torque” or rotational force to fasten a bolt or nut with less effort and more accuracy than standard wrenches. Purchase a…

-To determine which torque wrench capacity is best suited for an application, many factors must be considered. However, as a recommendation, use a torque wrench in the middle 50% of the overall capacity of the tool. This will result in longer tool life, ease of use for the operator and increased accuracy from micrometer adjustable type torque wrenches.

1/05/2013 · Learn how to use the TEKTON 3/8 in. Drive Click Torque Wrench (120-960 in./lb.). http://tekton.com/item/24325.

Using an air impact wrench (also known as mechanical torque gun or eletric torque wrench) can be often favoured by mechanics to save time. However, by not using a manual wrench you can damage the part being installed to the vehicle.

How to Use and Store a Torque Wrench Properly. Calibration: Most torque instruments have a factory calibration recommended interval of one year. Many torque instruments may need to be tested multiple times per year depending upon the usage and user needs.

Use a 2-foot-long wrench and apply 50 pounds of force, and you’ll have 100 ft-lb, which, happily, is just about as long as most lug wrenches, and as much force as most elbows are happy cranking on.

arm601-3 digital torque wrench product information manual manuel informations du produit manual información del producto english français español this manual contains important information regarding safety, operation, maintenance and storage of this product. ce manuel contient des informations importante concernant la securite, l’operation, la maintenance et le stockage de ce produit. este

The flat jaws of the open end make contact with only two corners of the nut. The head is offset by a small amount. This allows you to use the open end in a restricted space where the ring end won’t fit, turn the nut a small amount, then flip the wrench over, put it …

Norbar’s electronic torque wrenches provide versatile and easy to use wireless and traceable electronic torque and angle control. They provide an accuracy of ±1% between 20 and 100% of wrench capacity (up to 330 N·m) and are supplied with a torque and angle calibration certificate.

DTW Torque Wrench Instruction Manual checkline.com

How To Use A Torque Wrench Shop Tool Reviews

Whether your torque wrench has a digital or a mechanical scale set your Newton Metres (NM) or Foot Pounds (Ft lbs) as required. If you need to convert please see this article on torque conversions . Lets assume that the bolts you want to torque are M8 bolts holding on a cylinder head of a Rotax 912 engine and the manual states that they should be torqued to 22 NM (16.2 ft lbs).

Instructions for use The Manual Torque Wrench is a convenient tool for achieving the desired torque. It is easy to use, with a scale clearly indicating the two most common torque measurements,

English T KM customer serice tel: 020 8247 9300 e-mail customerserviceclasohlson.co.uk internet www.clasohlson.co.uk postal 10 – 13 Market Place, Kingston upon Thames, Surrey, KT1 1J

Use a 2-foot-long wrench and apply 50 pounds of force, and you’ll have 100 ft-lb, which, happily, is just about as long as most lug wrenches, and as much force as most elbows are happy cranking on.

To use a beam torque wrench, watch the gauge carefully until it reaches the torque required, then stop applying force to the handle. To use a click-type torque wrench, whether it’s a spring or split-beam, adjust the dial and lock it in to the required torque specification, then gradually tighten the fastener. When the torque limit is reached, you’ll feel and hear a “click” in the

21/05/2015 · A torque wrench is a specialty tool used in auto repair and some construction. Once calibrated, this tool provides “torque” or rotational force to fasten a bolt or nut with less effort and more accuracy than standard wrenches. Purchase a…

Use of Adapters When an adapter or extension is used on a torque wrench, it increases the torque range of the wrench. The formulae for computing torque when using an adapter or extension is

How to use the TEKTON 24325 3/8 in. Drive Click Torque

Proper Use of Pipe Wrenches Department of Mines

How to Use and Store a Torque Wrench Properly. Calibration: Most torque instruments have a factory calibration recommended interval of one year. Many torque instruments may need to be tested multiple times per year depending upon the usage and user needs.

Using an air impact wrench (also known as mechanical torque gun or eletric torque wrench) can be often favoured by mechanics to save time. However, by not using a manual wrench you can damage the part being installed to the vehicle.

USE OF ADAPTORS, EXTENSIONS AND UNIVERSALS Anytime an adaptor, extension or universal is used with a torque wrench in such a way that the fastener distance is different than the torque wrench square drive distance, an adjustment to the set torque is required to get proper fastener torque. 5 Fastener torque equals torque wrench square drive torque. Wrench setting is equal to desired …

DTW – Digital Torque Wrench Thank you! Dear Customers, Thank you for purchasing this digital torque wrench. This in-struction manual will help you to use the many features of your

A torque wrench is a very precise piece of equipment, therefore four tips you should know about ownership is never drop them, do not use them as a johnson bar to loosening tight fasteners, always keep them clean, and return the scale to it’s lowest torque range.

-To determine which torque wrench capacity is best suited for an application, many factors must be considered. However, as a recommendation, use a torque wrench in the middle 50% of the overall capacity of the tool. This will result in longer tool life, ease of use for the operator and increased accuracy from micrometer adjustable type torque wrenches.

Use the Checklist on pages 13 and 14 to select the best tool. The features listed on the Checklist The features listed on the Checklist correspond to the tips found on …

use with torque wrenches. Do not exceed their rated maximum torque. Always pull (DO NOT push) to apply torque. Adjust your stance to prevent a fall if something should give suddenly. Ratchet head torque wrenches must be checked for full (positive) engagement of the ratchet in the direction of use prior to applying a load on the wrench. Broken or slipping ratchets can cause injury. Periodic

When you are well acquainted with how to use a click torque wrench, you’ll be able to do a lot of households works very proficiently. Among differently typed torque wrenches, click type torque wrenches are most powerful compared to any other typed torque wrenches.

6 Avoiding damage to the torque wrench • Do not use the torque wrench as an impact tool. • Check the torque wrench, including accessories, prior to use.

The flat jaws of the open end make contact with only two corners of the nut. The head is offset by a small amount. This allows you to use the open end in a restricted space where the ring end won’t fit, turn the nut a small amount, then flip the wrench over, put it …

A socket wrench is a simple tool that allows you to turn nuts and some bolts with more ease than a regular wrench. The ratcheting feature allows you to keep the wrench connected to the bolt and eliminates the need to refit it with every turn of the bolt.

With a torque wrench set and the manufacturer’s torque value in hand, the problem is solved: A “clicker” torque wrench makes an audible click when you’ve reached the set torque, and with a “beam”-style wrench, you just watch the scale and stop at the right number.

How To Use A Torque Wrench The Proper Way Man Of Family

DTW Torque Wrench Instruction Manual checkline.com

1/05/2013 · Learn how to use the TEKTON 3/8 in. Drive Click Torque Wrench (120-960 in./lb.). http://tekton.com/item/24325.

Using an air impact wrench (also known as mechanical torque gun or eletric torque wrench) can be often favoured by mechanics to save time. However, by not using a manual wrench you can damage the part being installed to the vehicle.

To use a torque wrench properly, you first need to look up the torque specifications for the fastener you’re going to be using. If you don’t know, you don’t want to guess the specs, always turn to your trusty service manual. If you don’t have one, you can also check Google.

Use of Adapters When an adapter or extension is used on a torque wrench, it increases the torque range of the wrench. The formulae for computing torque when using an adapter or extension is

How to use a Torque Wrench. Making sure you have the right torque to your suspension, engine, and drivetrain components are critical. If you do not use a torque wrench or use an inferior tool, you probably not getting the bolts tight enough or overtightening.

PROPER USE OF TE SERIES TORQUE WRENCHES Main Pointer Dial Follow-up Pointer Fig. 5 – TE Series Torque Wrench Follow-up Needle Model I. Turn the dial until the main pointer is on zero.

Proper Use of a Click Adjustable Torque Wrench Tighten the bolts on the threads using the wrench till they get tightened. Adjust the wrench accordingly: All you have to do is loosen the adjustable dial.

A torque wrench is a tool that applies a specific torque to fasteners. It is usually in the form of a ratchet, also called a socket wrench . During the early 1900s, the over-tightening of bolts on water mains and steam pipes was prevalent.

A socket wrench is a simple tool that allows you to turn nuts and some bolts with more ease than a regular wrench. The ratcheting feature allows you to keep the wrench connected to the bolt and eliminates the need to refit it with every turn of the bolt.